What is the application of the blanching machine?

The blanching machine is versatile and can be used in various fields, including:

– Bottled and canned products

– Fruits and vegetables

– Pickles

– Dairy products

– Snack foods

– Low-temperature meat products

Blanching is used mainly for fragile items like wild vegetables, root vegetables (like carrots and asparagus), mushrooms, and fruit slices, serving as an essential step for quick freezing and dehydration.

Sterilization is crucial for ensuring the safety of food and extends shelf life by effectively killing harmful microorganisms. This process is suited for low-temperature meat, canned fruits, vegetable juices, pickles, jams, and more.

The machine accommodates various packaging types, including vacuum-sealed foods, soft bottles, and glass jars.

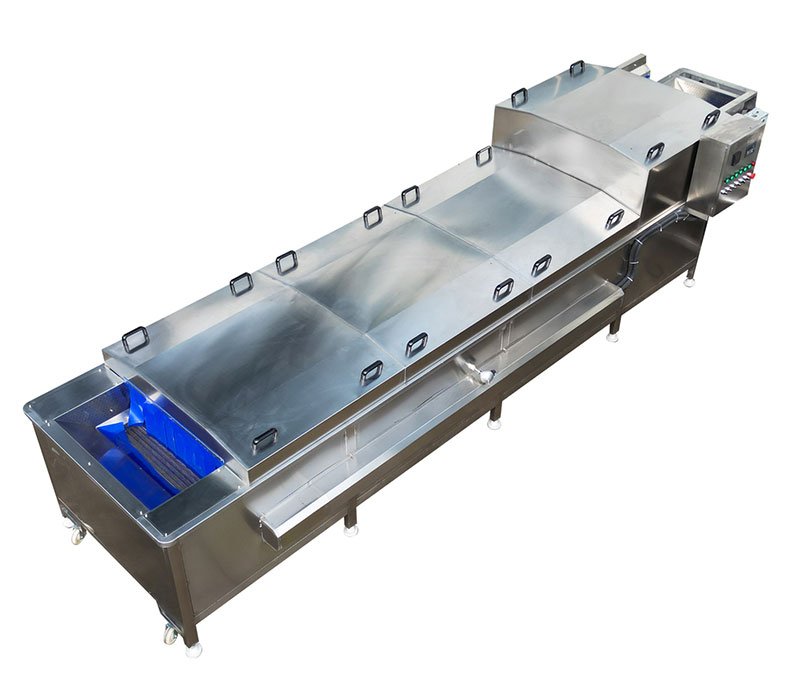

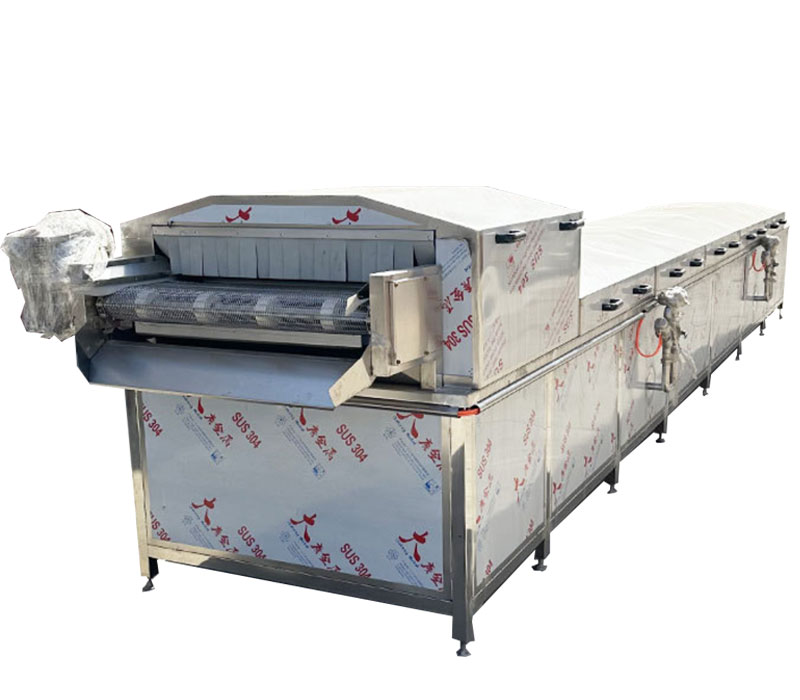

What is the installation and setup procedures for the blanching machine?

1. Equipment Placement:

Level the equipment feet at the designated location.

2. Utility Connections:

Connect water lines and electrical circuits.

3. Power Configuration:

Ensure correct power phase sequence; the green light on the phase sequence relay should be on.

4. Steam and Air Connections:

Connect the steam pipeline (pressure: 0.4 – 0.7 MPa).

Connect compressed air and adjust the relief valve (pressure: 0.6 – 0.8 MPa).

5. Temperature Adjustment:

Set the desired operating temperature.

6. Speed Adjustment:

Adjust conveying speed to required levels.

What are the steps for operating a blanching machine?

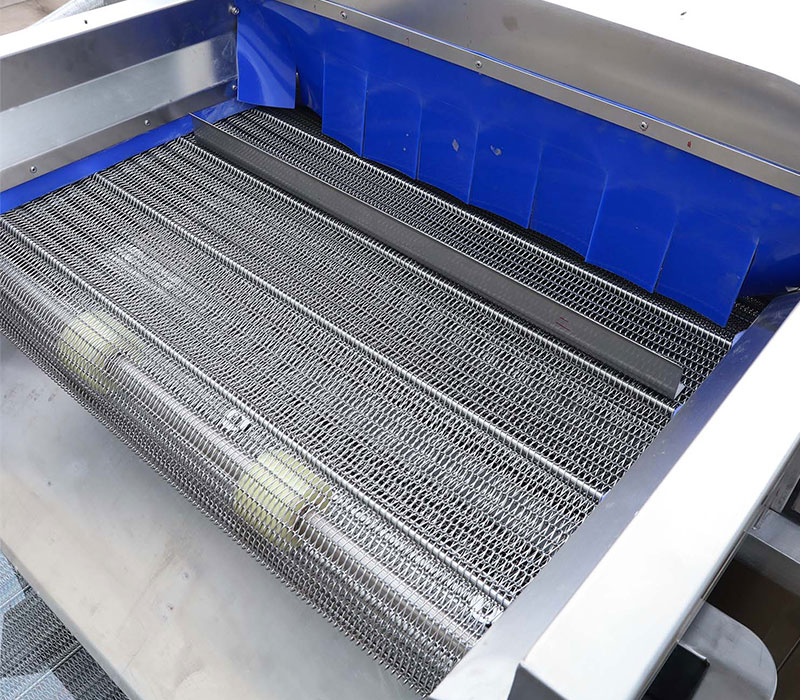

1. Fill the water tank with water until it reaches the overflow port.

2. Turn on the power and activate the steam switch.

3. Add the raw materials, such as green leafy vegetables and cans.

4. Collect the processed materials.

What precautions should be taken when using the blanching machine?

1. Avoid high-temperature burns from hot water, steam, and materials at the outlet while the equipment is running.

2. Do not insert your hands into the chain while the equipment is operational.

3. Do not adjust the conveying speed when the equipment is stopped.

4. The heating function should only be activated when the water tank is full.

What is the troubleshooting guide for blanching machine?

1. Fault: Steam does not heat

Reason: Compressed air is connected incorrectly

Solution: Adjust the connection of the compressed air

2. Fault: Trap does not discharge water

Reason: Trap is clogged

Solution: Clean the trap

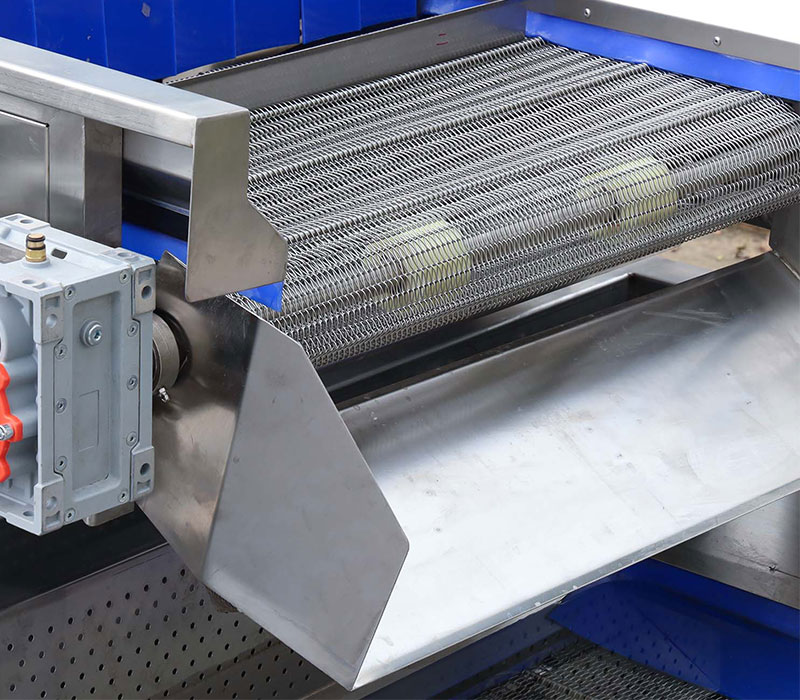

3. Fault: Chain conveyor is stuck

Reason: Mesh belt is too loose

Solution: Tighten the mesh belt

4. Fault: Water temperature does not reach the set temperature

Reason: Insufficient steam or clogged steam pipe

Solution: Increase air intake and clean the steam pipe

5. Fault: Water pump makes abnormal noise

Reason: Pump head is clogged

Solution: Remove foreign matter from the pump head

Leave a Reply