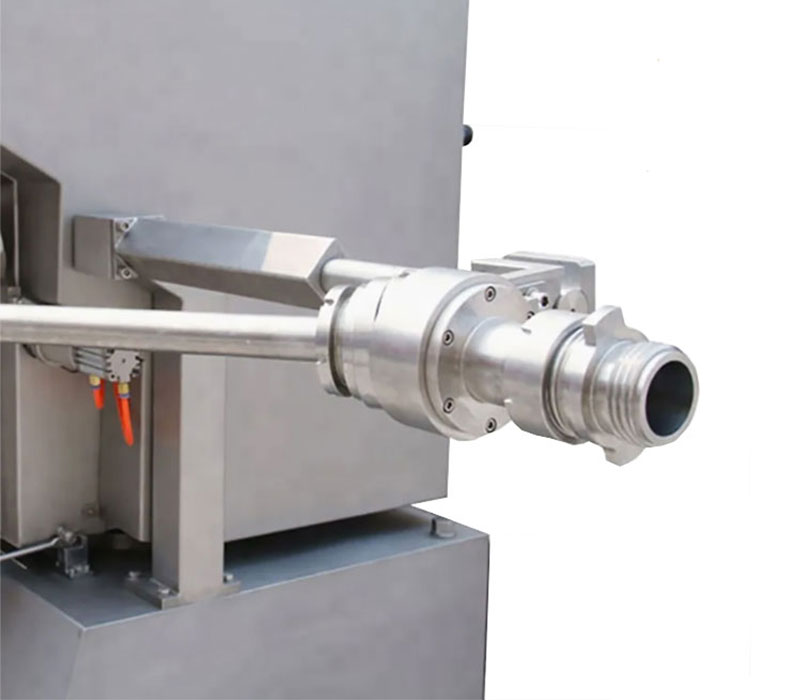

Why should I buy one great wall sausage double clipper machine?The great wall sausage double clipper machine offers a high degree of automation, enabling continuous and rapid sealing operations that significantly enhance overall production line efficiency. It utilizes high-quality materials such as heart-shaped buttons and premium aluminum wire to achieve stronger, more durable seals with an attractive appearance, ensuring consistent product quality. The machine is designed for ease of use, featuring a touch screen and intelligent control system that simplifies parameter adjustments and allows quick switching between multiple products, reducing operational complexity. Additionally, the great wall sausage double clipper machine is easy to maintain due to its simple structure, which facilitates cleaning and reduces the risk of failure. It can perform multiple processes with a single machine, thereby decreasing labor costs and increasing output. This equipment is ideal for companies aiming for high efficiency, consistent quality, and fully automated production, especially in large-scale manufacturing environments where productivity and product uniformity are critical advantages. What are the primary applications and types of products suitable for the aluminum wire clipping machine and the great wall sausage clipping machine?The aluminum wire sausage clipping machine is primarily used for traditional sausage products such as ham, hot dogs, bacon, and flavored sausages that require aluminum wire sealing after filling. It focuses on the sealing process and works in conjunction with filling equipment, making it ideal for small to medium-sized batch production where cost efficiency and sealing quality are priorities. This machine is suitable for companies seeking a reliable solution for sealing and cutting in a semi-automatic setup. The Great Wall sausage double clipper machine, on the other hand, is designed for large-scale, fully automated sausage production lines. It automates the entire process—from filling, threading, sealing, to cutting—making it suitable for high-volume manufacturing of a wide variety of sausages, including Italian, German, and flavored types. It supports multiple casing materials such as PVC, natural casings, and plastic sleeves, and is ideal for companies aiming for high productivity, consistent product quality, and ease of operation across diverse product specifications and varieties. How do the aluminum wire sausage clipping machine and the Great Wall sausage double clipper machine compare in terms of production efficiency and product quality?The aluminum wire sausage clipping machine offers reliable sealing for small to medium batch production, operating at speeds of 24-30 pieces per minute. Its mechanical sealing method ensures a tight, aesthetically pleasing seal, making it suitable for products like ham, hot dogs, and bacon. Its simple structure, low operational costs, and ease of maintenance make it an economical choice for businesses with moderate efficiency requirements, delivering consistent product quality with minimal complexity. However, it is primarily limited to the sealing stage and is best suited for small to medium enterprises with a focus on cost-effective, straightforward sealing solutions. The great wall sausage double clipper machine, equipped with PLC control and servo drives, significantly surpasses traditional models in production efficiency and consistency. It operates at speeds up to 120 sausages per minute and supports fully automatic filling, sealing, threading, and cutting processes. Its complex structure integrates multiple processes, supporting large-scale, continuous production with higher overall efficiency, greater capacity, and stable, high-quality output. This machine is ideal for large enterprises seeking automated, diversified, and high-volume production, with minimal operational training required thanks to its user-friendly touch screen and intelligent control system. Summary and Analysis: 1. Structure and Complexity: Aluminum wire sausage clipping machines are simple, primarily used for sealing, easy to maintain, and cost-effective. Automatic clipping machines are more complex, integrating multiple processes, requiring larger investments, suitable for large-scale continuous production. 2. Production Capacity and Efficiency: Aluminum wire sausage clipper machines are fast but limited to sealing; automatic clipping machines support fully automated operations, offering higher efficiency and capacity. 3. Operational Difficulty: Aluminum wire sausage clipper machines are easy to operate and ideal for operators with limited experience, while automatic Great Wall sausage double clipping machines with touch screens and PLC require minimal training. Recommendation:

Small and medium-sized enterprises, companies with limited budgets, and those mainly focused on sealing should opt for aluminum wire clipping machines. Conversely, large enterprises aiming for automated, high-capacity production with diverse product types should choose the automatic clipping machines to maximize efficiency and product consistency. What are the differences in maintenance, troubleshooting, and safety between the aluminum wire sausage clipping machine and the Great Wall sausage double clipper machine?The aluminum wire sausage clipping machine features a simple structure with a low failure rate, and its maintenance mainly involves regular cleaning of rollers and replacement of aluminum wire and punching needles. Its key factors are the linearity of the aluminum wire and the flexibility of the clipping needle, and it is recommended to use aluminum wire that meets standards to ensure smooth operation. In contrast, the automatic clipping machine employs advanced PLC control, servo motors, and pneumatic systems, making it more technically complex but also resulting in a low failure rate. Maintenance for the automatic model includes lubrication, cleaning, and sensor and control system checks. It is equipped with multiple protective devices to ensure safe operation. Safety for both machines requires strict adherence to operating procedures, avoiding operation in environments lacking pressure or water, and performing regular maintenance. The automatic Great Wall sausage double clipper machine has an intuitive user interface, is easy to operate after training, and facilitates troubleshooting. Overall, the aluminum wire sausage clipper machine is suitable for small to medium enterprises due to its simple design and ease of maintenance, while the Great Wall sausage double clipper machine is better suited for large enterprises that demand high efficiency, stability, and diversified production, despite higher maintenance complexity and costs. | |

Leave a Reply