Why should I choose an automatic chicken skinner machine for my poultry processing operation?

A chicken breast skinning machine offers a highly efficient and hygienic solution for skinning poultry parts such as chicken breasts, necks, and legs. It automates the skin removal process, significantly reducing manual labor and increasing production capacity—able to process up to 2 tons of poultry per hour with a skinning rate of around 99%. The machine ensures a clean, damage-free skinning process, minimizes product cracking or breaking, and results in bright, fresh-looking products. Its ease of operation and ability to connect with large-scale slaughtering lines help lower labor costs, improve overall efficiency, and boost profitability for poultry processing businesses.

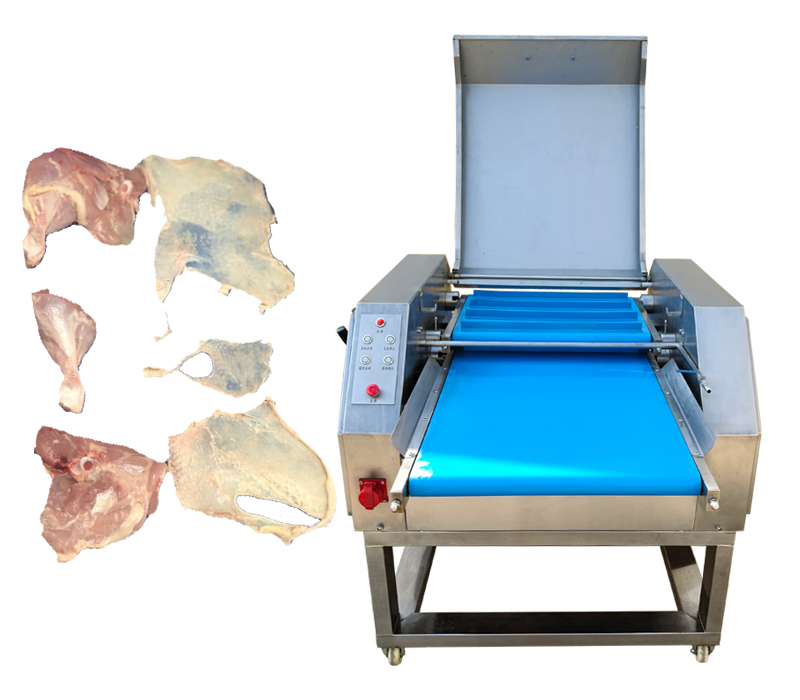

What is the application of the automatic chicken skinner?

1.Poultry Processing Plants

Designed for efficient skin removal from various poultry parts, including chicken breasts, chicken necks, and chicken legs, as well as duck necks and duck breasts. It automates the skinning process, improving speed and consistency.

2. Large-Scale Slaughterhouses

Integrated into automated slaughter lines to streamline the skinning of poultry and other animals such as pork. The machine’s automatic conveying, positioning, and skinning features significantly reduce manual labor and enhance processing efficiency.

3. Meat Deboning and Processing Facilities

Perfectly suited for use during deboning operations, where quick and hygienic removal of skin is essential. Its ability to connect seamlessly with deboning lines helps save time and reduce production costs.

4. Frozen and Packaged Meat Industries:

Provides high-quality, skinless poultry products for retail, frozen foods, and prepared meal production, ensuring a clean and presentable appearance.

5. Export-Oriented Poultry Business

Ensures hygienic, uniform skinning that meets international standards, supporting export requirements for high-quality meat products.

6. Specialty Meat Products Production

Ideal for producing skinless chicken breasts, deboned chicken parts, and skinless duck or pork cuts for culinary uses, processed efficiently and with minimal damage to the meat.

This automatic chicken skinner’s versatility in handling chicken breasts, necks, legs, duck necks, duck breasts, and pork makes it a valuable asset for any poultry or meat processing operation aiming to enhance productivity, product quality, and cost savings.

What safety precautions should I follow before and during the cleaning of the automatic chicken skinner?

1. Wear work clothes resistant to cleaning agents and disinfectants, and protect your eyes and skin.

2. During cleaning, pay special attention to parts that come into contact with meat, such as the peeling roller.

3. Do not point the high-pressure water gun at the control panel, motor, reducer, or bearings.

4. After cleaning, lubricate all moving parts promptly with food-grade lubricants to ensure smooth operation.

What are the basic steps to properly start and operate the automatic chicken skinner?

1. Ensure the equipment feet are leveled and securely locked.

2. Tighten all bolts and lock the conveyor belt wheels to ensure stability.

3. Confirm that all line connections are secure and properly connected.

4. Connect the machine to a 3-phase power supply.

5. Press the green start button to power on the equipment and observe the conveyor belt’s movement.

6. If the conveyor belt moves in the wrong direction, adjust the wiring accordingly.

7. If needed, connect the water pipe for additional cleaning or processing requirements.

How do I operate the automatic chicken skinner to start processing chicken legs?

- Place the chicken legs onto the feed conveyor.

- Position the tools or containers at the output end to receive the skinned chicken legs.

- Turn on the equipment and perform a quick check to ensure everything is functioning properly.

- Once confirmed, officially start the production process for continuous skinning.

What are the recommended daily and weekly maintenance procedures for the automatic chicken skinner to ensure its proper operation?

Daily Maintenance:

1. Turn off and stop the machine when it is not in use to prevent unnecessary idling.

2. Clean all impurities, dirt, and residues from both inside and outside of the equipment daily to maintain hygiene and prevent buildup.

Weekly Maintenance:

1. Check all nuts and bolts at each joint of the equipment to ensure they are tight and secure; tighten or replace any that are loose or falling off.

2. Inspect the electrical pipelines for any damage or wear to prevent electrical issues.

3. Examine the motor and bearings for proper lubrication; regularly replace or top up lubricating oil to ensure smooth operation.

Caution:

– The equipment should be operated, maintained, and serviced by a dedicated, trained personnel.

– Timely and correct maintenance is essential for the equipment’s normal operation and longevity. Neglecting maintenance can lead to abnormal operation, increased wear and tear, and a reduced service life.

What should I do if the automatic chicken skinner does not turn on when I press the run button or if the skinning effect is poor?

If the machine does not turn on:

Possible Cause: The machine may be stuck in a certain position.

Solution: Adjust the relevant parts to ensure there are no obstacles preventing movement.

Possible Cause: Line break or electrical disconnection.

Solution: Check all electrical lines and repair any disconnected or damaged wiring.

Possible Cause: Insufficient voltage supply.

Solution: Verify that the power supply meets the required voltage specifications.

Possible Cause: The inverter plug is loose.

Solution: Tightly connect the inverter plug.

Skinning effect is poor and less chicken skin falls off:

Possible Cause: The chicken thigh or chicken breast is not placed correctly on the conveyor belt.

Solution: Ensure the poultry parts are positioned properly in the middle of the conveyor to achieve optimal skinning results.

Leave a Reply