What shapes can I achieve with the meat chicken breast trimming shaping machine?

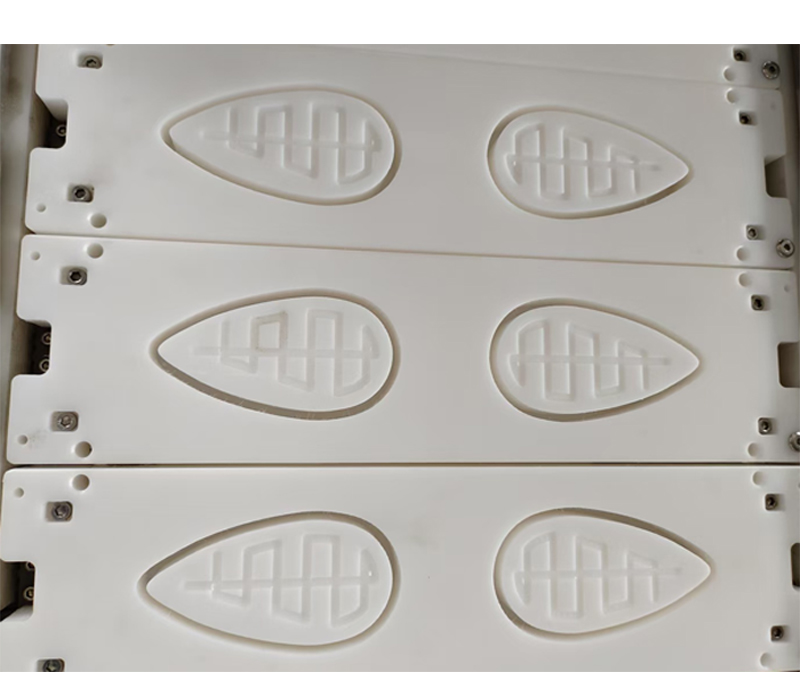

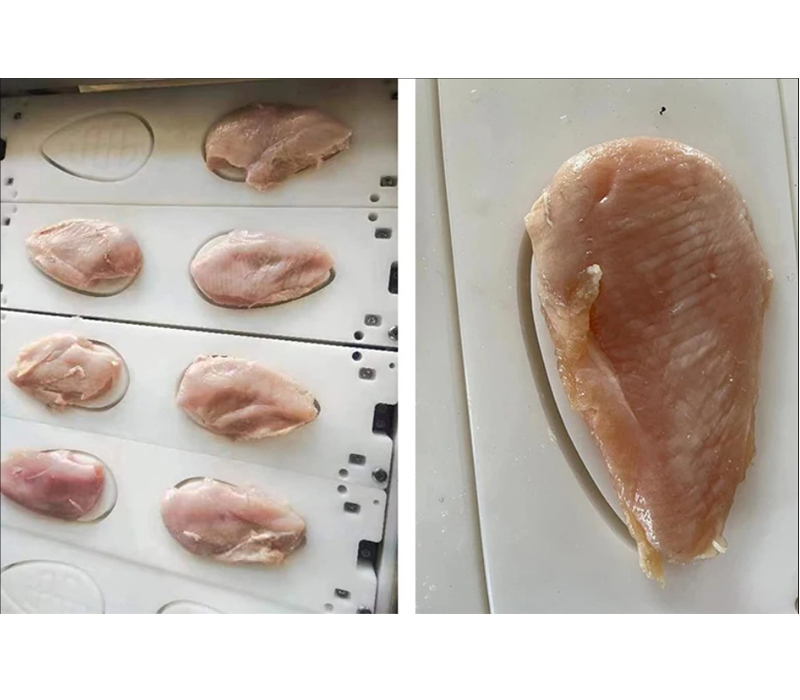

The chicken breast meat trimming machine is highly versatile, capable of cutting various raw materials such as fresh beef, pork, chicken breast, and duck breast. We can provide square, rectangle, triangle, oval, round, maple leaf and more. This flexibility allows you to produce popular products like steak, chicken steaks, and other meat cuts. The meat trimming cutting machine ensures that the meat retains its structural integrity during the cutting process, leading to enhanced flavor and texture in the final products. Whether you’re preparing for a restaurant menu or a catering service, this machine can meet your diverse meat shaping needs

What are the steps for the PLC setting process in the chicken breast meat trimming machine?

Setting up the PLC for the steak trimming machine involves a straightforward process designed for user efficiency. Here are the steps:

Enter Parameter Setting Interface: Begin by accessing the parameter setting interface on the machine.

Click “Parameter Setting” Button: Locate and click the “Parameter Setting” button to proceed.

Select Product Type: Choose the specific product type or shape you want to process before setting parameters.

Set Various Parameters: Adjust the necessary parameters according to your production requirements.

– Example parameters to enter or adjust:

– Plate feed speed: factory value is 80

– Low-speed parking speed: factory value is 60

– Positioning step value: factory value is 2250

– Positioning correction value: factory value is 100

– Outer frame pressing time: factory value is 70

– Outer frame lifting time: factory value is 10

– Inner push plate return time: factory value is 10

– Inner push plate working time: factory value is 20

– Repeated pressing plate air jet time: factory value is 8

– Pressing plate times: factory value is 3

Save Settings: Once all adjustments are made, confirm that the settings are correct and click the “Return” button to exit the setting interface.

Manually Cancel the Operation: If you need to cancel the current operation or setting, you can easily do so by clicking the “Manual Cancel” button.

By following these steps, you can complete the PLC setting process for the meat trimming cutting machine, ensuring that all parameter settings align with operational requirements, thereby enhancing production efficiency and maintaining product quality.

How do I handle instrument fault detection in the chicken breast meat trimming machine?

If you encounter an instrument failure with the meat trimming machine, you can follow these steps for efficient troubleshooting:

Check Air Source Input: Ensure that the air source input is functioning normally, as an insufficient air supply can cause operational issues.

Inspect Button Switch: Examine the surface of the button switch for any foreign matter or debris that may hinder its operation. Ensure it is clean and free from obstructions.

Restart the Machine: Restarting can often resolve temporary issues. Turn off the power and wait for 10 seconds before powering it back on to reset the system.

Seek Professional Help: If the problem persists after following these steps, it’s advisable to consult a professional maintenance technician for repairs. Alternatively, you can return the machine to the sales unit for servicing.

By taking these steps, you can effectively troubleshoot instrument faults and maintain the optimal performance of your meat trimming machine.

What are the safety precautions to follow when using the meat trimming cutting machine?

Ensuring safety while operating the meat trimming cutting machine is essential to avoid accidents and injuries. Here are some important safety precautions to follow:

Ground the Power Supply: Before installation, ensure that the power supply is properly grounded to minimize the risk of electrical shock.

Turn Off Power Before Cleaning: Always switch off the power before cleaning the machine to prevent accidental activation and ensure a safe cleaning environment.

Power Off When Changing Molds: Prior to changing any molds, make sure to turn off the power to avoid any unexpected movements of the machine during the process.

Avoid Casual Insertion into Operating Structure: Never reach into the operating structure without careful consideration. Always prioritize personal safety and keep hands and other body parts clear of moving components.

By adhering to these safety precautions, you can help maintain a safe working environment when using the meat trimming cutting machine

Leave a Reply