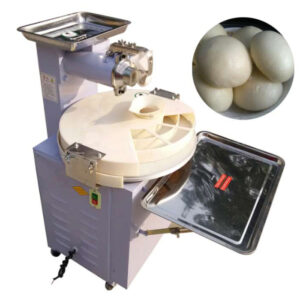

What’s the weight this electric dough divider machine could make?

The dough weight of the electric dough divider machine can be adjusted according to the user’s requirement. By changing the different dough outlet, the machine can produce dough weight ranging from 5 grams to 500 grams. This flexibility allows for customization based on specific needs.

What is the dough weight error for the electric dough divider machine?

The weight error for the VER electric dough divider machine is only 2 grams. For example, if the desired weight for each dough portion is 100 grams, the machine may produce portions that weigh between 98 grams to 102 grams. This level of error is considered very low and generally acceptable in the baking industry, as it does not significantly affect the overall quality or consistency of the final baked products.

What is the dough and water ratio for the electric dough divider machine?

The dough and water ratio for the electric dough divider machine refers to the amount of water that can be used relative to the amount of flour in the dough. In the case of the mentioned machine, it can accept a maximum flour:water ratio for 1:0.7. This means that for every 100 parts of flour used, a maximum of 70 parts of water can be added. The ratio is typically expressed as a percentage, so a 70% water ratio indicates that the water content can be up to 70% of the flour content.

What is the application for this electric dough divider machine?

The electric dough divider machine is a versatile piece of equipment that has a wide range of applications in the food industry. Its main function is to automatically divide the dough into small, equal-sized portions. Here are some of the common applications for this machine:

Biscuits: The dough divider machine can be used to create evenly sized portions of dough for biscuits. This ensures consistent baking and uniformity in the final product.

Buns: Whether it’s for burger buns, hot dog buns, or any other type of bread roll, the dough divider machine can accurately divide the dough into equal portions, resulting in uniform and professional-looking buns.

Dumplings: Making dumplings by hand can be time-consuming and challenging to achieve consistent sizes. The dough divider machine simplifies the process by quickly and accurately dividing the dough into equal portions, making it ideal for dumpling production.

Bread: From baguettes to sandwich loaves, the dough divider machine can handle various types of bread dough. It ensures that each portion of dough is of the same size, promoting even baking and consistent quality.

Tapioca Pearls and Taro Balls: These popular ingredients in bubble tea and other Asian desserts require precise portioning. The dough divider machine can efficiently divide the dough into small, uniform balls, ensuring consistent cooking and texture.

Pizza: Whether it’s for a pizzeria or a fast-food restaurant, the dough divider machine can help streamline the pizza-making process. It can divide the dough into equal portions, saving time and effort for the pizza makers.

The wide application of the electric dough divider machine makes it a valuable asset in various food establishments, including fast food restaurants, bakeries, snack bars, and pasta processing units. Its ability to automate the dough portioning process ensures consistency, efficiency, and improved productivity in food production.

What is the operation process for the electric dough divider machine?

1) Firstly, knead the dough into long strips to ensure sufficient amount of dough supplied by the machine without continuous dough.

2) Put enough flour in the flour bucket to ensure uninterrupted flour spreading.

3) Turn on the power, turn on the switch, put the dough kneaded into long strips into the feeding port, the machine will start to work normally, be careful not to put your hand into the feeding port.

4) The size of the divided dough can be adjusted. When the rotary knob of the governor rotates clockwise, the dough becomes larger, and vice versa. You can also replace the face regulator sub-size.

5) After each use, the machine should be cleaned in time.

After each using, following below tips:

6) Turn off the power and unplug the machine.

7) Remove any remaining dough from the feeding port and discard it.

8) Remove the flour bucket and empty any leftover flour.

9) Use a brush or cloth to clean the machine, removing any dough or flour residue.

10) Pay special attention to the cutting blades and dough auger, ensuring they are free from any debris.

11) Wipe down the exterior of the machine with a damp cloth to remove any dirt or stains.

12) Allow the machine to dry completely before storing it in a clean and dry area.

13) Regularly inspect and maintain the machine according to the VER manufacturer’s instructions to ensure its proper functioning.

What is the lead time for electric dough divider machine?

The manufacturing time for the electric dough divider machine is typically 10-15 days. And the sea shipping time can vary depending on the destination country. It can range from 10-50 days or even longer in some cases. The exact duration is influenced by factors such as distance, customs procedures, and any potential delays during transit. Therefore, the total delivery time for the dough divider machine would be the sum of the manufacturing time (10-15 days) and the sea shipping time (10-50 days), resulting in an overall delivery time that can range from approximately 20 to 65 days, or even longer in certain situations if your seaport too remote.

If this electric dough divider machine power can be customized?

The electric dough divider machine can be quoted with either 110V 60Hz or 220V 50Hz single phase voltage options. However, if your area follows a different standard voltage system, we can customize the voltage accordingly.

What is the warranty do you offer?

The warranty for electric dough divider machine includes 12 month warranty for the entire machine body, ensuring that any defects or malfunctions within this period will be repaired or replaced free of charge.

Furthermore, even after the warranty period expires, the company provides long-life technical support for the VER electric dough divider machine. This means that customers can still receive assistance and guidance regarding any technical issues or inquiries they may have, ensuring the continued functionality and performance of the machine.

Leave a Reply