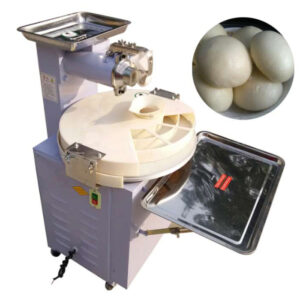

Why should I buy one continuous dough divider?

VERFOODSOLUTIONS continuous dough divider is a highly valuable investment for bakeries and food producers seeking to significantly improve efficiency, consistency, and product quality. It enables high-speed, automated division and rounding of dough, supporting segmentations from 8-30g up to 100-500g, with a capacity of up to 10,000 pieces per hour. Built with durable stainless steel, wear-resistant and self-lubricating parts, imported motors, and German transmission systems, it supports continuous 12-hour operation with a lifespan of up to 10 years. The large ergonomic hopper, food-grade non-stick blades, and adjustable parameters allow for precise, hygienic portioning and easy maintenance. Its user-friendly control panel, space-efficient design, and ability to operate independently or integrate into existing production lines make it versatile for small artisanal bakeries or large industrial facilities. Overall, it reduces manual labor, lowers operational costs, guarantees consistent product appearance, and supports a wide range of baked goods—from bread and rolls to pizza and pastries—making it an essential tool for boosting productivity and maintaining high-quality standards.

What are the primary applications of the continuous dough divider across different fields and production environments?

The dough divider is versatile enough to handle medium-soft dough, with or without oil, meeting the needs of different recipes and formulations. This machine is ideally suited for producing consistent-sized dough portions for products including sweet bread, sandwich bread, tousled bread, pizza crust, mooncake crust, sesame balls, bread rolls, dinner rolls, and handmade bread. Its ability to automatically divide and round dough ensures uniformity in size and shape, which improves product appearance and quality while reducing labor costs and production time.

The continuous dough divider is widely used in various bakery and food production settings due to its efficiency and precision. Key application areas include:

- Large-Scale Bakeries: For continuous, high-volume production of bread, rolls, and specialty baked goods with consistent size and shape.

- Chain Restaurants and Food Service Chains: To quickly produce uniform dough portions for various menu items, ensuring product consistency across locations.

- Central Kitchens and Food Processing Plants: For mass production of baked products such as sandwich bread, sweet bread, pizza crust, mooncake crust, sesame balls, and more, streamlining the manufacturing process.

- Baking Education and Training Institutes: To teach students and trainees about dough handling, division, and shaping techniques with consistent results.

- Research & Development Laboratories: For creating new recipes and testing dough formulations, as the machine allows precise control over portion size and shape.

- Specialty and Artisan Bakeries: For producing handcrafted bread, dinner rolls, and other artisanal baked goods with uniformity and efficiency.

Overall, this machine helps improve production speed, ensure product uniformity, reduce labor costs, and meet the diverse needs of various baking and food processing applications.

What are the different operation options available for this continuous dough divider, and can it be customized further?

The machine offers five versatile operation modes to accommodate various production needs, allowing you to divide dough into different weights and quantities efficiently,you can choose either of the below 5 solutions:

- Dividing one dough at a time (100-500g, up to 2,000 dough/hour)

- Dividing two dough simultaneously (50-250g, up to 4,000 dough/hour)

- Dividing three dough at once (30-120g, up to 6,000 dough/hour)

- Dividing four dough simultaneously (10-60g, up to 8,000 dough/hour)

- Dividing five dough at a time (8-30g, up to 10,000 dough/hour)

Additionally, the machine can be equipped with an immersing device that combines two dough into one, for example, merging two 500g dough into a 1,000g dough, which can then be rounded by the rounder machine. This feature provides greater flexibility for your production line, enabling you to customize dough sizes and weights as needed. Overall, this machine is designed to optimize efficiency and customization, making it a valuable asset for various baking and food production applications.

How do I properly adjust the variable frequency to control the continuous dough divider machine’s speed and ensure safe operation?

To adjust the variable frequency, locate the adjustment control, which ranges from 15 Hz to 50 Hz, with 50 Hz being the maximum. First, ensure the machine is connected to power and the assembly is in the “on” position—press the switch up to activate it. Open the assembly cover carefully. For adjustment, turn the frequency control clockwise to increase the speed (up to 50 Hz) or counterclockwise to decrease it.

Note: The recommended operating range is around 10-15 Hz for short adjustments; running below 15 Hz for extended periods can cause motor overheating. After setting the desired frequency, press the start button to begin operation. Always ensure safety covers are in place during normal operation, and only remove protective covers during testing or maintenance. Proper adjustment of the frequency ensures optimal performance and prevents motor damage.

How do I properly adjust the continuous dough divider cutter scale and ensure optimal operation?

To adjust the cutter scale, first check if the scale is off-center. If it is, pull out the cap and position it correctly. If the component feels loose, gently turn or loosen it as needed, then fine-tune the position by moving it up or down until it is properly aligned. After fine-tuning, tighten the adjustment securely, lift it back into position, and tilt it back properly. For safety and optimal operation, replace and tighten the cap securely.

Next, adjust the frequency setting according to your production needs—up to a maximum of 50 units for precise control. Once adjustments are complete, you can resume normal production, ensuring the cutter operates smoothly and accurately. Regular fine-tuning helps maintain consistent quality and efficiency in your processing.

How should I properly clean the continuous dough divider machine after use to ensure optimal hygiene and maintenance?

After finishing production, run the machine a little longer to ensure all dough is cleared out. Let it run until no dough remains inside—this may require a few extra steps. Then, lower the frequency control to stop the machine safely. Once stopped, open the lid carefully.

Use a cloth to thoroughly clean all areas, including underneath components, the belt, and the inside of the hopper, ensuring no dough residue is left. It’s important to clean after each use to maintain hygiene and prevent buildup. After cleaning, lower the frequency setting again, start the machine briefly to rotate horizontally, and wipe the return path and other accessible parts.

Once cleaning is complete, reassemble the cover securely. When shutting down, press the stop button and turn the machine off completely to stop the oil pump, preventing unnecessary oil circulation and ensuring proper maintenance. Regular cleaning helps keep the machine in optimal condition and prolongs its lifespan.

How do I properly maintain and lubricate the continuous dough divider for long-term operation?

The continuous dough divider requires regular lubrication to ensure smooth and efficient performance. It uses a food-grade lubricant, which is visible in designated parts of the machine. When the lubricant level is low, simply unscrew the refill cap, pour in the recommended food-grade lubricant, and securely replace the cap.

In addition, there are caps and tubes (located at various points) that contain lubricant or may accumulate excess oil or dirt. These should be unscrewed and cleaned regularly to prevent buildup. Use a cloth or suitable cleaning tool to wipe away any excess oil or debris.

Regularly check and replenish the lubricant as needed, following the VERFOODSOLUTIONS’s instructions, to maintain optimal operation and extend the lifespan of the machine. Proper maintenance ensures hygiene, safety, and consistent performance.

What is the troubleshooting for the continuous dough divider?

To adjust the dough weight, you will use the weight adjustment handwheel and the adjusting screw.

1. To Increase Dough Weight:

- First, loosen the adjusting screw.

- Then, slightly loosen the locking screw.

- Gently pull the entire stop upwards slightly.

- Finally, tighten the locking screw.

- The weight of the dough is adjusted by the adjusting screw.

2. To Decrease Dough Weight:

- Select the stop with the largest difference.

- Slightly loosen the locking screw.

- Tighten the adjusting screw to reduce the dough weight.

- After adjustment, tighten the locking screw.

Important Notes:

- Refer to a weight measurement ruler for accurate adjustments.

- If the two dough pieces are uneven, the position of the stop block can be adjusted.

- If you encounter persistent issues or suspect a blockage, ensure the machine is stopped, then unscrew the fixing screw to remove the copper piston for cleaning. After cleaning, reinstall the copper piston in the correct order.

Leave a Reply