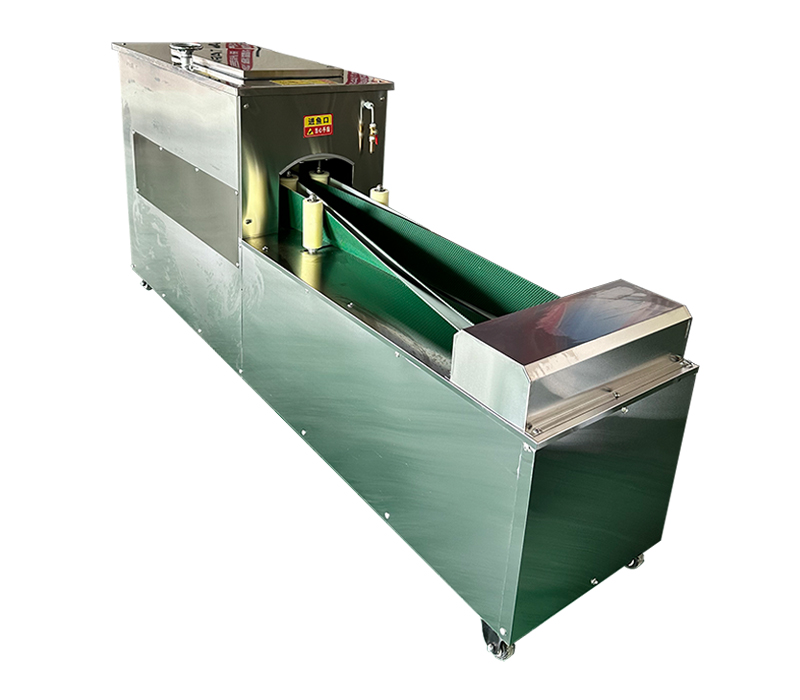

Fish Splitting Machine

Main Benefits

- Suitable for various fish types splitting

- Feeding platform available optional

- Offers option to open fish back or belly

- Automatic adjustment, no manual work needed

- No jamming issues, continuous operation

- Fresh-keeping function maintains freshness always

- Handles semi-thawed fish with ease.

- Reliable performance, easy maintenance

- Fish body protected, no damage

Overview

VERFOODSOLUTIONS Fish splitting machine is designed with durability and hygiene in mind, made from stainless steel to ensure wear-resistance and corrosion-resistance. The machine operates smoothly and quietly, with a one-button operation that allows for efficient and convenient processing of fish. The fish cutting knife edge can be adjusted to accommodate different fish sizes and types, making it suitable for processing a variety of small fish including hairtail, small river fish, saury, osmanthus fish, native crucian carp, upturned mouth fish, grouper, stone drum fish, flower fork fish, horse mouth fish, yellow croaker, and more.

The fish splitting machine’s design features an automatic control system that eliminates the need for manual adjustment, allowing for a high yield and minimizing waste. The stainless steel body and wading parts are easy to clean and maintain, making it simple to keep the machine running smoothly. The machine can process 50-120 fish per minute, making it an efficient solution for processing large quantities of fish quickly and easily. With its ability to process fish in semi-thawed or thawed state, this machine helps maintain the freshness of the fish. Its compact design, coupled with easy cleaning and maintenance features, makes it an ideal solution for businesses looking to optimize their fish processing operations while adhering to strict safety and quality standards. The machine’s versatility allows it to handle a wide range of fish types and sizes, making it an invaluable asset for various establishments in the food service industry, including restaurants, hotels, aquatic shops, and other catering businesses.

Videos

Features

- Stainless steel structure made of food-grade material.

- One-button operation for simple usage ease.

- Throughput rate of up to 24 fish per minute.

- Processes fish up to 9kg in weight.

- Adjustable knife depth for whole& halved fish.

- Elastic fish inlet for easy fish loading.

- Anti-slip fish outlet for smooth fish removal.

- Automatic adjustment adapts to fish sizes perfectly.

- Multi-function knife set for versatile operation.

- One-button operation for simple usage ease.

- Convenient cleaning system for easy maintenance.

- Stainless steel chain transmission for stable power.

- Openable side door for daily cleaning access.

- Specially processed blade for sharp cutting edge.

- Lifting adjustment method for accurate control.

- Waterproof electrical system for improved safety.

- Large-capacity processing for high-volume use.

Specifications

| Model | FSKM-25 | FSKM-40 | FSKM-90 |

| Capacity(Pcs/min) | 24-30 | 24-30 | 24-30 |

| Voltage(V) | 110/220/240/380/415 | 110/220/240/380/415 | 110/220/240/380/415 |

| Power(Kw) | 3.0 | 2.5/3.0 | 3.0 |

| Fish Weight(Kgs) | 0.05-2.5 | 0.05-4.0 | 2.5-9.0 |

| Weight(Kgs) | 45 | 120 | 175 |

| Dimension(mm) | 850*510*880 | 1800*600*900 | 2210*610*1100 |

FAQ

Why should I buy one unit fish splitting machine?

Increased productivity: The fish splitting machine processes 24-30 fish per minute, equivalent to more than 5 workers, dramatically boosting your production capacity.

Cost-effective: While the initial investment may be significant, the machine saves on long-term labor costs and increases overall efficiency.

Consistent quality: With a 95% success rate, the machine ensures uniform processing quality, maintaining the integrity and appearance of the fish.

Versatility: Suitable for various fish types and sizes (0.5 to 9 kg), making it adaptable to different processing needs.

Improved safety: Automated operation reduces the risk of workplace injuries and improves overall working conditions.

Enhanced hygiene: Less manual handling means better food safety standards.

Easy to use: Simple operation and maintenance reduce the need for specialized skills.

Long-term investment: Unlike human workers, the machine doesn’t require salary increases or benefits, providing continuous returns on your investment

What kind of fish can I cut on this fish splitting machine?

Our fish splitting machine is versatile and can efficiently process a wide variety of fish species, including:

Gilthead sea bream, Sea bass, Nile tilapia,Shi drum, Common dentex, White seabream, Atlantic mackerel, Horse mackerel, Red porgy,Trout,Salmon, Cod, Haddock,Pollock, Sardines,Herring, Yellowtail,Red snapper, Grouper, Catfish, Carp, Perch, Pike, Whiting Mullet.

This versatility ensures that the machine can meet diverse processing needs across different fish species commonly found in commercial fishing and aquaculture operations. Whether you’re dealing with saltwater or freshwater fish, our machine is designed to handle a broad spectrum of fish types, making it an ideal solution for various seafood processing facilities.

Is it safe to operate the fish splitting machine?

Yes, it is very safe to operate our fish splitting machine, our machine comes with below safe features.

Closed Design:

The machine features a fully enclosed structure, completely shielding all dangerous parts during operation. This design significantly reduces the risk of operator contact with moving components.

Waterproof Electrical System:

Incorporating advanced waterproofing and sealing measures, the electrical system effectively prevents leakage risks. This allows for safe operation even in humid environments.

One-Button Operation:

Simple, intuitive button controls minimize the possibility of operational errors and reduce direct contact between the operator and the machine.

Automated Fish Processing:

The machine automatically handles the entire process from input to output. Operators only need to place fish at the inlet, eliminating the need for manual interaction with sharp components.

Emergency Stop Function:

Equipped with a prominent emergency stop button, allowing for immediate machine shutdown in case of any unforeseen incidents.

Robust Construction:

Built with high-grade stainless steel, the machine boasts a stable and reliable structure, ensuring safe operation without risk of structural failure.

Anti-Slip Design:

The conveyor belt features anti-slip material, reducing the risk of fish slippage and enhancing operational safety.

Comprehensive User Manual:

Each machine comes with a detailed operating manual, providing clear instructions to guide operators in correct and safe equipment usage.

Regular Maintenance Alerts:

The machine is programmed with maintenance reminders to ensure all components are regularly checked and serviced, maintaining optimal safety standards.

Safety Certifications:

Complies with international safety standards and bears relevant safety certifications, assuring users of its reliability and safe design.

These comprehensive safety features ensure that our fish killing machine not only delivers high efficiency but also prioritizes operator safety and

How should I choose the right fish splitting machine?

When you choose fish splitting machine, you should consider the following factors:

Fish Size:

Large machine: Suitable for fish up to 9kg in weight

Small machine: Processes fish up to 2.5kg in weight

Choose based on the typical size of fish you process.

Space Availability:

Large machine: Requires more floor space

Small machine: More compact, suitable for smaller facilities

Budget:

Large machine: Generally more expensive due to higher capacity

Small machine: More affordable option for smaller operations

Versatility:

Large machine: Can handle a wider range of fish sizes

Small machine: More specialized for smaller fish

Safety Features:

Small machine: Highlighted for its fully enclosed design, enhancing safety and hygiene

Large machine: Safety features not specifically mentioned, but likely includes standard safety measures

Energy Consumption:

Large machine: Typically higher energy consumption

Small machine: Generally more energy-efficient

In summary, choose the large machine if you process larger fish, need high throughput, and have space and budget for it. Opt for the small machine if you mainly process smaller fish, have limited space, or run a smaller operation prioritizing safety and hygiene. Always consider your current needs and future growth plans when making your decision.

What is the daily maintenance required for the fish splitting machine?

Proper daily maintenance is crucial for ensuring the longevity, efficiency, and hygiene of your fish splitting machine. Here are the key maintenance tasks:

Daily Cleaning:

Thoroughly wash the machine after each use, especially parts contacting fish

Use food-grade detergent and a soft brush; avoid corrosive cleaners

Dry completely to prevent water-induced corrosion

Tool Maintenance:

Regularly check tool sharpness; sharpen or replace as needed

Apply food-grade lubricants to prevent rust

Adjust tool angles and positions for optimal cutting accuracy

Transmission System Care:

Inspect and lubricate chains, bearings, and other transmission parts

Check and adjust belt tension

Replace worn transmission components promptly

Electrical System Inspection:

Examine wires, plugs, and switches for any issues

Ensure all waterproof seals are intact

Contact a professional electrician if abnormalities are detected

Fish Inlet and Outlet Maintenance:

Check elasticity and cleanliness of inlets and outlets

Remove any debris or blockages

Ensure smooth operation of adjustment mechanisms

Conveyor Belt Upkeep:

Verify belt tension and alignment

Clean the belt surface to maintain anti-slip properties

Repair or replace damaged belts promptly

Lubrication:

Regularly lubricate designated parts as per instructions

Use only food-grade lubricants to avoid contamination

Fastener Inspection:

Check and tighten all screws, nuts, and other fasteners

Replace any worn or damaged fasteners

Operator Training:

Regularly train operators on correct usage and daily maintenance procedures

By diligently following these maintenance steps, you can:

Extend the lifespan of your equipment

Maintain optimal operational efficiency

Reduce the risk of unexpected breakdowns

Ensure consistent product quality and food safety

Remember, while daily maintenance is crucial, it’s also important to schedule regular professional servicing to address more complex maintenance needs and ensure your machine continues to operate at peak performance.