Chicken Patty Nuggets Production Line

VER 300mm chicken patty nuggets production line include forming, battering, flouring (pre-dusting), bread crumbs coating, frying, IQF, could form different shapes and sizes and shapes(round shape, square shape, oval shape, triangle shape, star shape etc.) like meat

patty/potato cake/fish pie/shrimp cutlet/fish cutlet/beef cutlet by changing the different mold.

Overview

300mm Chicken Patty Nuggets Production Line

VER 300mm chicken nuggets production line could automatically finish the procedure of forming, battering, predusting(flouring), breading, frying, IQF, it could produce products of different shapes by changing different forming molds, suitable for making hamburger patties, chicken nuggets, fish patties, vegetarian nuggets, potato cakes, vegetable patties, pumpkin patty, pork shashlik and other foods.

Meets HACCP standards, made of high-quality stainless steel 304 and waterproof non- metallic materials, the patty nuggets process line is very durable, high capacity, stable performance, suitable for meat processing plants, catering industry, dispatching center, food distribution centers, food factories and other units.

Videos

Features

Specifications

- ModelOverall DimensionTank CapacityPowerBelt Width

- FM300 Chicken Patty Nuggets Machine1750*800*1650nn200-400kgs/hour0.92Kw300mm

- PM300 Predusting Machine2000*780*1450mmInput Height 800-900 mm

Output Height 800-900 mm1.35Kw300mm - BMJ300 Waterfall Battering Machine1500*900*1250mmInput Height 800±50 mm

Output Height 800±50 mm0.82Kw300mm - TBMJ300 Tempura Battering Machine1550*800*1250mmInput Height 800±50 mm

Output Height 800±50 mm0.45Kw300mm - BMX300 Bread Crumbs Coating Machine2000*850*1520mmInput Height 700-800mm

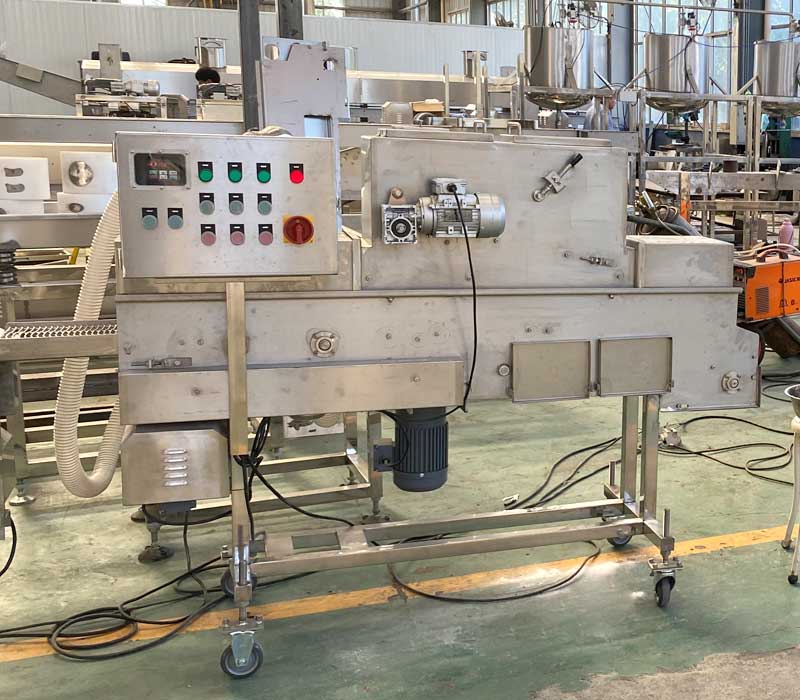

Output Height 700-850 mm1.17Kw300mm

The 300mm Chicken patty nuggets production line comprises of the following machinery:

300mm Chicken Patty Nuggets Machine VER 300mm chicken patty nuggets machine could complete the filling, molding and output process of minced meat, and form different sizes and shapes(round shape, square shape, oval shape, triangle shape, star shape, etc.) for making hamburger patties, chicken nuggets, fish nuggets, vegetarian nuggets.

300mm Predusting Machine VER 300mm predusting machine(flouring machine) is specially designed for flouring various products like chicken nuggets and patties in coating process procedure. Predusting machine coats the bottom of the products by the layer of the flour on the transferring belt, it coats the surface of the products by the unique belt pouring the flour evenly to the passing products on the belt.

300mm Waterfall Battering Machine VER 300mm Waterfall battering machine could make an even coating for the surface of meat patties, nuggets, potato pie, pumpkin pie made from chicken, beef, meat, seafood, by transporting the slurry from the slurry tank to the spraying system through a slurry pump, and then form a waterfall-type spraying slurry, which is suitable for relatively small, thin, light and easily broken products.

300mm Dip Tempura Battering Machine VER 300mm Dip tempura battering machine could be connected with forming, preduster/flouring machine, breading machine and frying machine to form one full contentious chicken nuggets &patty processing line. Also this battering machine could be used alone to batter hamburger patties, chicken nuggets, fish-flavored hamburger patties, potato patties, pumpkin pies, small meat buns, meat balls which are made of meat, poultry, seafood and vegetable etc, it is an ideal sizing equipment for fast food shops, distribution centers and food factories.

300mm Bread Crumbs Coating Machine VER 300mm bread crumbs coating machine coats evenly the chicken, beef, meat and seafood a top layer by outpouring the crumbs from the hopper and a bottom layer while the products are passing the conveyor. This breading machine is applied after battering, the products enter into the below of belt, the bottom and side product are wrapped by the bread chaff then the upper of product is covered by the bread chaff from hopper, pressing by compression roller (it’s convenient to adjust the thickness of bread chaff between top and bottom of belt), the extra bread crumb will be flow off when pass the air knife, at last transform the product to the next process.