French Fries Batch Fryer

Main Benefits

- Automatic discharging and optional loading to reduce labor intensity

- Customized pot diameter for specific frying capacity demand

- User-friendly operation with PLC temperature control

- Accurate temperature control for durability and stability

- Even mixing and frying for consistent results

- Versatile for different frying processes

- Smooth and brightly colored food, improving product quality

- Middle oil layer heating for oil quality extension

- Versatile frying with oil preservation

- Stirring for consistent and vibrant frying results

- Easy movement with 360°rotating casters

- Hygienic, durable, and economical stainless steel body

- Suitable for one-person operation

Overview

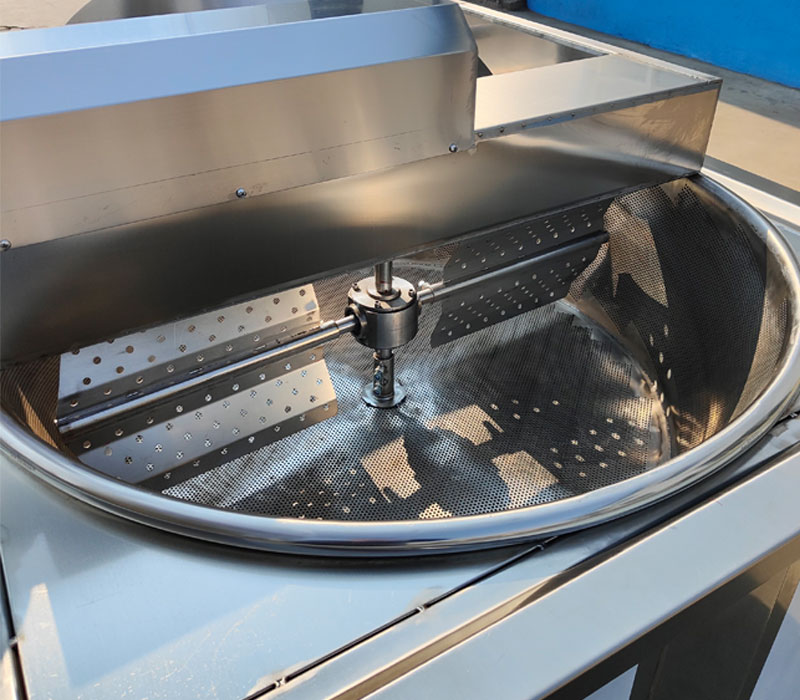

Introducing our state-of-the-art french fries batch fryer that incorporates an innovative heating technique located in the middle of the oil layer, guaranteeing precise temperature control in both the upper and lower oil layers. This groundbreaking approach effectively minimizes the oxidation level of the frying oil, preventing the rise in acid value and significantly prolonging the oil’s lifespan. With the inclusion of an automatic filtration feature, our machine consistently maintains the cleanliness of the frying oil, resulting in a consistent and superior quality of fried products. This not only enhances the overall product quality and extends its shelf life but also adds exceptional value to your offerings. Equipped with a sophisticated digital display thermostat, adjusting the temperature is effortless. Once the desired frying temperature is set, the machine seamlessly takes over and accurately maintains the temperature, eliminating the risk of manual errors and the possibility of compromised product quality due to negligence.

Our french fries batch fryer comes equipped with an automatic loading hopper and a discharge port. The former effectively prevents burns caused by hot oil splashing when pouring raw materials into the pot, significantly reducing the likelihood of employee injuries. The latter ensures consistent frying time, simplifying the process and enhancing convenience. During the frying process, the equipment automatically stirs to ensure the uniformity of fried products and prevent them from sticking to each other due to pressure. For products that tend to float, the tapping mixing method is utilized, while for those that tend to sink, the bottom-scraping mixing method is employed. Our machine offers a variety of mixing methods suitable for frying various types of food. Rest assured, your food will attain the perfect color, aroma, and taste, ensuring a delightful culinary experience for your esteemed customers.

Videos

Features

- Electric or gas heating with reliable and efficient burner

- Automatic stirring for even frying and prevention of adhesion

- Tapered bottom for easy cleaning and dough residue removal

- Check valve to prevent oil from flowing back into water pipe

- Observation glass tube and oil drain valve for accurate water level measurement

- Convenient water adding valve for uninterrupted frying

- Observation glass tube and oil drain valve for water lines

- Cooling measures to prevent water boiling prematurely

- Automatic temperature control for oil (0-300 degrees)

- Option for oil-water separation or pure oil filtration system

- Food residue filter and drain outlet for oil saving

- Independent distribution box for easy operation

- Multiple models available for pot diameter

- Optional automatic discharging

- Scraper optional for specific demand

- Quick heating up in just 10 minutes

Specifications

| Model | Adjustable Frying Temperature(℃) | Power(Kw) | Voltage(Voltage) | Pot Diameter (mm) | Pot Dimension(mm) | Machine Dimension (mm) | Discharge Way

|

| BFM-500 | 0-300 | 24 | 220/240/380/415/440/Customized | 500 | 500*500*400 | 880*620*930 | /Manual/Hydraulic/Electric Optional |

| BFM-1000 | 0-300 | 36 | 1000 | 1000*500*400 | 1380*620*950 | ||

| BFM-1200 | 0-300 | 48 | 1200 | 1200*500*400 | 1580*620*1000 | ||

| BFM-1500 | 0-300 | 60 | 1500 | 1500*700*400 | 1880*620*1000 | ||

| BFM-1800 | 0-300 | 60 | 1800 | 2000*2000*1000 | 1900*800*850 |

FAQ

What is the working principle for the french fries batch fryer?

A french fries batch fryer works by immersing the food in hot oil, resulting in a crispy and delicious texture. The french fries batch fryer consists of a heating element, usually located at the bottom of the appliance. It is responsible for heating the oil to the desired temperature for frying. Once the batch frying machine is turned on and the desired temperature is set, the heating element starts to heat the oil. It takes some time for the oil to reach the desired temperature, usually indicated by a light or sound signal on the fryer. The food to be fried is placed in the frying pot and then carefully lowered into the hot oil. It is essential to avoid overcrowding the frying pot to ensure even cooking and prevent the food from sticking together.

Once the food is immersed in the hot oil, the frying process begins. The high temperature of the oil causes the moisture inside the food to evaporate rapidly, creating a crispy exterior. The food continues to cook until it reaches the desired level of doneness. After the food is cooked, turn the fryer over to drain and remove the fried food.

Does this french fries batch fryer save oil?

This french fries batch fryer saves oil very much, add oil and water to french fries fryer machine, oil with a relatively low density occupies the upper half of the container, and water with a relatively high density occupies the lower half of the container. Place the electric heating tube horizontally on the oil layer of the container. When frying, the food is in the oil layer, and a horizontal cooler and a forced circulation fan are installed at the oil-water interface to cool the water, so that the temperature of the oil-water interface is controlled below 55°C. The food residue produced when frying food falls from the high-temperature oil layer and accumulates in the lower-temperature water layer at the bottom. At the same time, the oil contained in the residue returns to the oil layer after being separated by the water layer. The residue that falls into the water can be discharged with the water. These residues will not affect the oil quality and extend the life of the frying oil.

What is the operational mechanism underlying the french fries batch fryer apparatus?

The french fries batch fryer is versatile and can be used for a wide range of applications, including frying meat, nuts, seafood, and snacks, providing a convenient and efficient way to achieve delicious and crispy results.

Meat: It can be used to fry various types of meat such as fried chicken, salted duck, chicken tenders, tenderloin, meatballs, beef jerky, pork belly, chicken legs, pig trotters, and more. The machine ensures that the meat is cooked evenly and achieves a crispy and golden exterior.

Nuts: The machine is also suitable for frying nuts like peanuts, green beans, broad beans, sunflower seeds, and others. It provides a quick and efficient way to roast nuts, enhancing their flavor and creating a crunchy texture.

Seafood: The deeper frying machine can be used to fry a variety of seafood, including various fish species, shrimps, scallops, sea reds, small fish larvae, squid rings, squid larvae, and fish tofu. It helps to achieve a crispy and delicious coating while retaining the natural flavors and moisture of the seafood.

Snacks: The machine is also suitable for frying snacks like crispy rice and other similar items. It ensures that the snacks are perfectly cooked, crispy, and evenly browned, making them more enjoyable to eat.

What is the security for french fries batch fryer?

The ideal oil temperature for deep frying with a machine can vary depending on the specific type of food being cooked. However, a common temperature range for deep frying is typically between 350°F (175°C) and 375°F (190°C).Maintaining a consistent oil temperature is important to achieve optimal results. If the oil is too cool, the food may absorb excess oil and become greasy. On the other hand, if the oil is too hot, the food may burn on the outside while remaining under cooked inside.

What is the security for french fries batch fryer?

The french fries batch fryer is designed with utmost consideration for safety, incorporating various features to prevent accidents and guarantee secure operation. One of the notable safety features is the built-in timer, which allows users to set a specific frying duration. This feature ensures that the food is not left in the fryer for an extended period, reducing the risk of overcooking or burning. Additionally, the automatic shut-off feature adds an extra layer of safety. It enables the batch fryer to turn off automatically after a predetermined time, preventing any potential hazards that may arise from forgetting to switch off the machine. Furthermore, the french fries batch fryer is equipped with overheating protection. This safety mechanism actively monitors the temperature of the fryer and automatically shuts it down if it exceeds a certain threshold. By doing so, it prevents the oil from reaching dangerous temperatures that could lead to fires or other accidents.

What is the warranty policy for the french fries batch fryer?

The warranty for french fries batch fryer includes 12 month warranty for the entire machine body, ensuring that any defects or malfunctions within this period will be repaired or replaced free of charge. Furthermore, even after the warranty period expires, the company provides long-life technical support for the french fries batch fryer. This means that customers can still receive assistance and guidance regarding any technical issues or inquiries they may have, ensuring the continued functionality and performance of the machine.

What is the maintenance for the french fries batch fryer?

By following below maintenance and cleaning practices, you can keep your french fries batch fryer in good condition and ensure the longevity of its performance.

Regular cleaning: After each use, allow the machine to cool down completely. Wash all the frying pot, lid, and heating element and wash them with detergen, rinse thoroughly and dry them.

Deep cleaning: Periodically, deep clean the machine to remove built-up grease and residue. Fill the fryer with a mixture of water and a grease-cutting detergent. Heat the solution to a boil and let it simmer for a few minutes. Turn off the machine and let the solution cool. Scrub the interior surfaces with a non-abrasive brush or sponge, paying attention to areas with stubborn residue. Rinse thoroughly with clean water and dry completely.

Oil change: Regularly changing the oil is crucial for maintaining the quality of fried food. Over time, oil can break down, become rancid, and affect the taste of the food. Follow the manufacturer’s instructions for oil change frequency, but as a general guideline, it is recommended to change the oil every 8-10 uses or when it becomes dark, thick, or starts emitting a strong odor.

Oil storage: If you need to store the oil between uses, strain it through a fine-mesh sieve or cheesecloth to remove any food particles. Store the oil in a cool, dark place in a tightly sealed container to prevent oxidation.

Regular inspection: Check the power cord, plug, and any other electrical components regularly for any signs of damage. If you notice any issues, have them repaired or replaced by a professional.

Safety precautions: Ensure the machine is placed on a stable, heat-resistant surface away from flammable materials. Never leave the machine unattended while in use.