What are the step-by-step instructions for setting up and using the hydraulic chapati press machine after receiving?Check Grounding: Ensure the machine is securely grounded for safety.

Set Heating Plates: Adjust the upper and lower heating plate temperatures to your desired levels.

Connect Power: Plug in the power cord to a suitable power source.

Enter Setup Mode: Press the “Set” button to enter setup mode.

Configure Parameters: Use the control options to set the desired parameters (temperature, pressure, time, etc.).

Confirm Settings: Press the “Enter” button to save and confirm the settings.

Start the Machine: Turn on the machine and insert raw materials for testing.

Test and Adjust: Observe the results and make adjustments to the parameters if necessary.

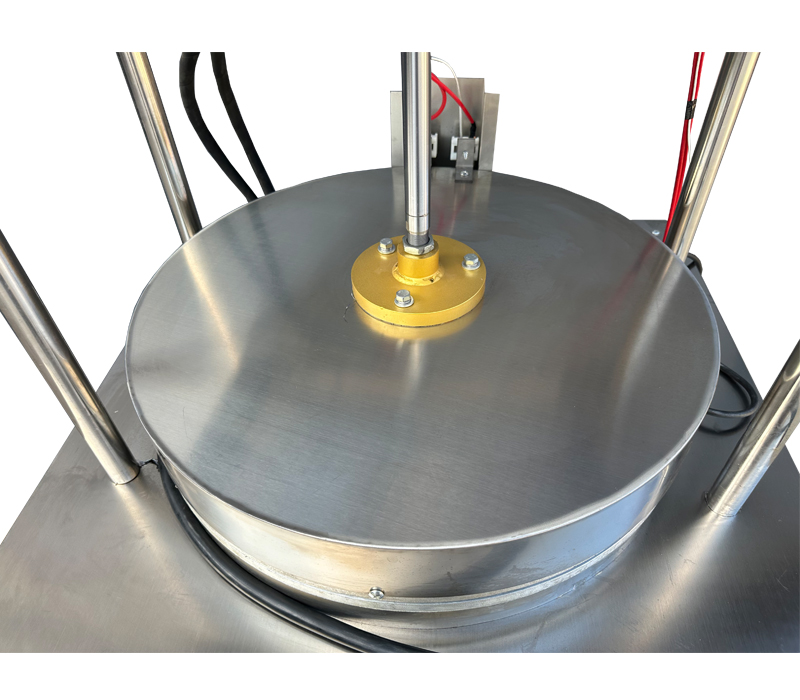

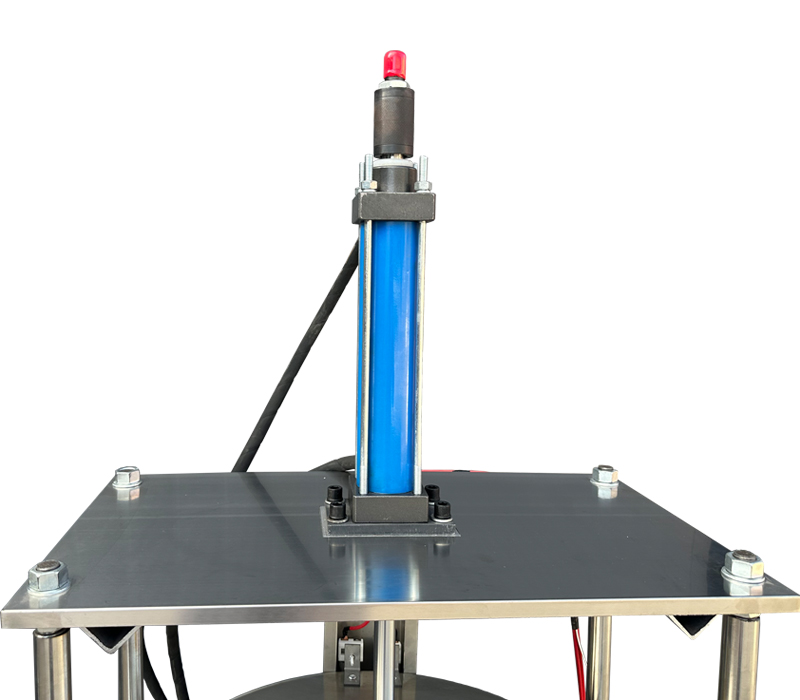

Final Operation: Once satisfied with the results, proceed with regular production. How do I set the temperature and crust thickness on the hydraulic chapati press machine?To adjust the temperature, use the two digital controls on the electrical control box: the left control for the upper heating plate and the right control for the lower heating plate. Turn these controls to set your desired temperature levels. To adjust the chapati thickness, loosen the nut on the upper plate, then turn the air-assisted rod forward or backward to increase or decrease the thickness. Once satisfied with the adjustment, tighten the nut on the upper plate. How do I set the automatic lowering time on the hydraulic chapati press machine?The lowering time is the duration after the heating plate is lowered from top to bottom before the upward buffer begins, and it can be adjusted by changing the number on the digital control display. The automatic lowering time determines the size of the chapati. To adjust it, use the digital control screen to set the desired time. A longer lowering time results in a larger chapati size, while a shorter time produces a smaller chapati. If the chapati tends to break, shorten the automatic lowering time; if the chapati is too small or not breaking, increase the time. How do I adjust the various time settings on the hydraulic chapati press machine?Slight Rise Time: This controls how long the upper plates move slightly upward after the automatic lowering process. To adjust it, access the control panel and set the desired duration. A longer slight rise time will produce softer chapati.

Automatic Rise Time: This is factory-set and typically does not require adjustment. It is the time the press plates automatically rise after all processes are complete. If needed, consult the manual or technical support for adjustments.

Chapati Heating Time: This determines the chapati doneness. To adjust, modify the pressing time or temperature settings on the control panel. Longer pressing time or higher temperature results in a more cooked or darker chapati, while shorter time or lower temperature produces a lighter chapati.

Always refer to the user manual for detailed instructions on entering setup mode and adjusting each parameter. How should I properly clean and maintain the hydraulic chapati press machine to ensure safe and efficient operation?-During operation, place the measured dough on the press plate, press the start switch, and press down. After the heating cycle, use a high-temperature film to prevent sticking on the die.

-Keep hands away from the press plate during operation to avoid injury, and keep flammable items away from the press plate for safety.

-Regularly check the power cord and protective sheath for damage, and replace any damaged parts to ensure safe operation.

-Protect the electrical box under the machine from moisture at all times.

-After work, allow the machine to cool naturally; do not use cold water to cool the work surface, as this can cause deformation.

-If any part of the work surface becomes too cold during operation, the heating element may be damaged and should be inspected and replaced immediately.

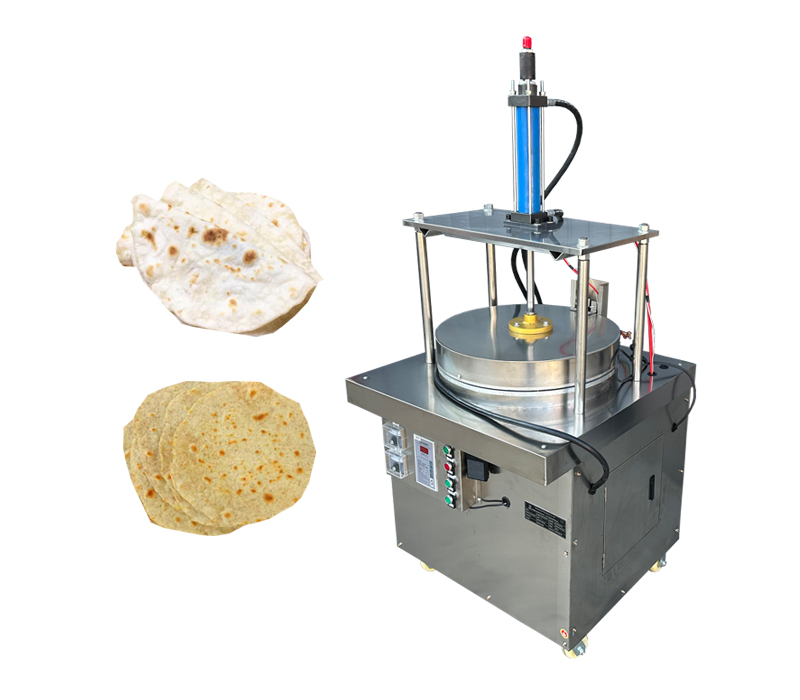

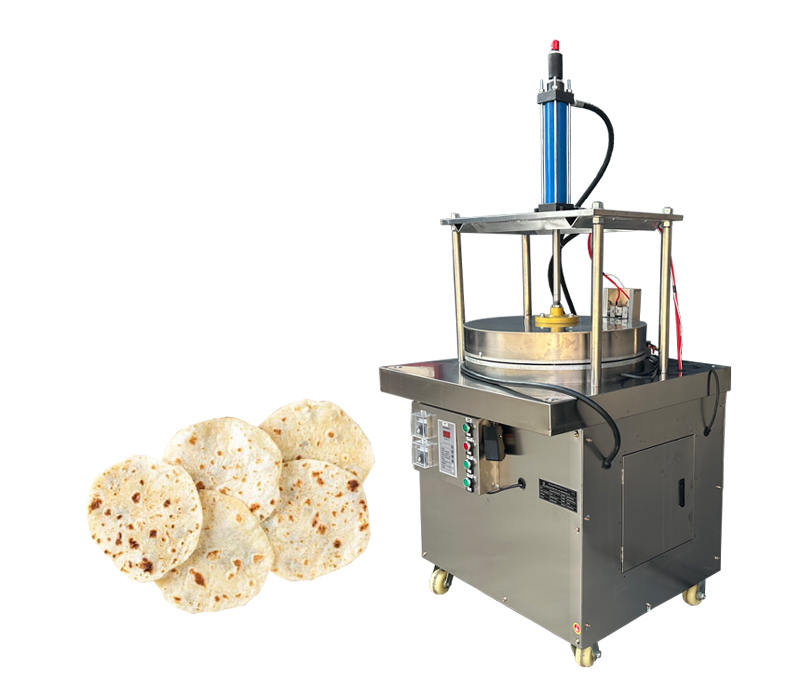

To clean the press disc, wipe it with steel wool, then clean with a cloth, and finish by wiping with an oily cloth to maintain its condition. Are there any important points I should be aware of when using the hydraulic chapati press machine for the first time?This machine comes factory-tested, with preset adjustments for temperature, time, and air pressure. When preparing dough with regular flour, use a flour-to-water ratio of approximately 1:0.6 to 0.7 to ensure the dough is firm yet soft enough for processing. Also, pay attention to the two cups at the bottom of the machine: if you notice water on the left side, drain it; similarly, drain the oil (gasoline oil) from the right side as needed to maintain proper operation. | |

Leave a Reply