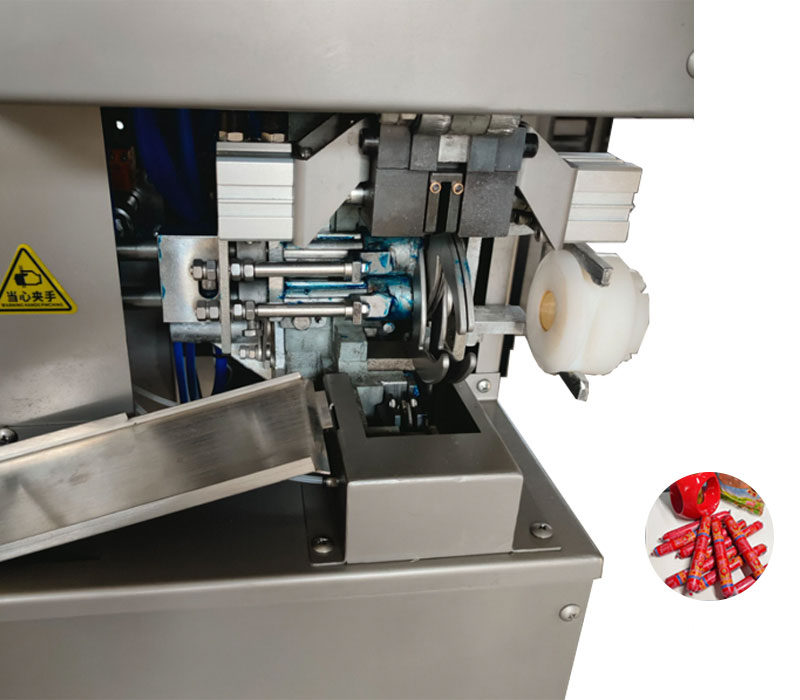

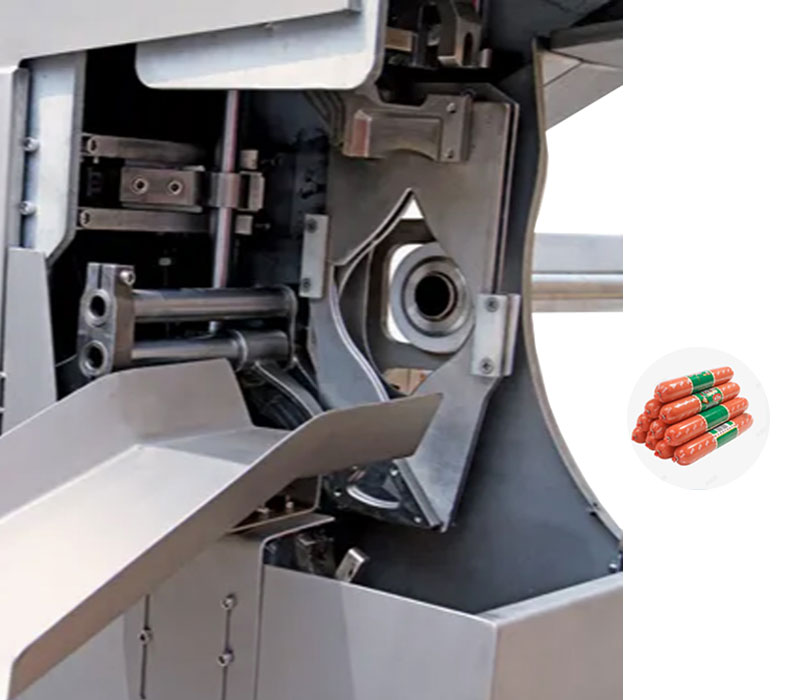

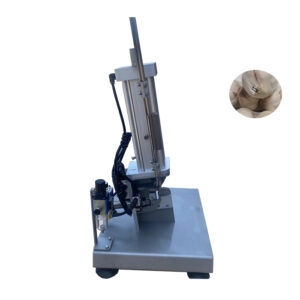

Why Should I Buy the sausage clipping machine?This new-generation aluminum wire double sausage clipping machine is independently developed by our company, combining advanced mechanical transmission with servo motor, PLC, and touch screen control for precise, simple, and efficient operation. Its design ensures a low malfunction rate, high speed, and excellent sealing results. Using aluminum wire for sealing, it creates a beautiful heart-shaped buckle that guarantees a secure, long-lasting seal. The machine can seal a variety of materials, including nylon film, shrink film, and casings with folding diameters from 25 to 80 mm, with matching dies and aluminum wire for different casing types. It can be integrated with various quantitative filling machines to form an automated production line, with optional dual filling tubes to significantly boost production efficiency. All key components are made of high-quality, professionally processed materials, ensuring stable performance and reliable quality. The clipping speed is adjustable from 1 to 9 levels, reaching up to 120 clips per minute for a single machine. It features interchangeable K1, K2, and K3 dies, with casing folding diameters ranging from 20 to 100 mm. The machine includes an automatic cutting function, with a choice of 0 to 9 pieces, and the stretching distance is adjustable from 36 to 100 mm to meet different product fullness requirements. The clipping center height is adjustable from 950 to 1000 mm, and multiple safety devices ensure safe operation. Constructed from durable, hygienic high-quality stainless steel, all product-contact components meet food safety standards, making it easy to clean and maintain. The machine features advanced PLC control with an intuitive display, variable frequency speed regulation for smooth operation and energy savings, and a safety protection system that automatically shuts down in case of burst detection. Its versatile design makes it suitable for use in meat, food, and non-food applications, handling a wide variety of products with reliable, stable performance. What types of sausages can this sausage clipping machine produce?This sausage clipping machine is compatible with a wide range of casing types, including nylon shrink film, nylon film, composite film, and PVDC film, enabling the production of numerous popular sausages worldwide. For nylon shrink film casings, it can produce American-style hot dogs, German frankfurters, Austrian wieners, and some varieties of Polish kielbasa. Nylon film casings are suitable for making salami, pepperoni, Bockwurst from Germany, and Middle Eastern merguez. Composite film casings are ideal for Middle Eastern sujuk, Hungarian kolbász, and Italian mortadella-style sausages. PVDC film casings are primarily used for premium hot dogs and frankfurters in Europe and the US, as well as processed sausages requiring tight sealing and airflow control. This versatility allows the machine to produce a diverse array of high-quality sausages to meet global demand. What are the compatible sizes of the sausage clipping machine?Our clipping machine accommodates four die sizes—K1, K2, K3, and K4—which include φ2.1, φ2.45, φ2.7, φ2.9, and φ3.2 aluminum wire coils. The aluminum wire double-buckle clipping machine offers diameter options of φ12, 15, 25, and 30mm, suitable for making protein casing ham sausages. When selecting a sausage filling and clipping machine, consider a dual-purpose model with a kinking device at the discharge port, capable of handling weights from 3 to 1000 grams. Please specify your sausage type before ordering to ensure compatibility. What aluminum wire buckle sizes are compatible with this clipping machine and how should I choose the right one?This product is suitable for a variety of aluminum wire buckles, with common specifications including 2.1mm, 2.45mm, and 2.9mm, which are widely used in the market. If your ham is relatively thin or small in diameter, larger-diameter aluminum buckles may not be suitable; in such cases, opt for thinner aluminum wire. Since these buckles are consumables used in plastic ham processing, it’s advisable to keep a sufficient supply on hand to ensure smooth operation. What is the typical range for casing fold diameter for the sausage clipping machine, and can it be customized to specific sizes?The standard casing fold diameter typically ranges from 20mm to 100mm. However, if you require a specific size—such as a very thin sausage with a diameter of only 10mm—we offer customization options. After technical consultation with our workshop, we can tailor ham sausage clipping machines to meet your exact size requirements. What should I do if the aluminum wire is not straight or the punch is not flexible?If the aluminum wire is not straight, inspect it for bends or deformations and replace it if necessary. If the punch is not flexible or sticking, check for damage or deformation and replace the punch to ensure proper clipping performance. Regular maintenance and inspection can help prevent these issues and keep the machine operating smoothly. How do I properly start and operate the sausage clipping machine to ensure safe and synchronized filling and clipping?To start the sausage clipping machine, first press the power button on the back after connecting it to the power supply and air pump. If filling is needed, press the continuous filling button. For clipping cards after filling, connect the card device at the front and press the link button to synchronize both machines; failing to do so will prevent them from operating at the same speed. Additionally, always operate the machine with proper pressure and water supply, and avoid touching the clip clamping area with your hands to ensure safety. | |

Leave a Reply