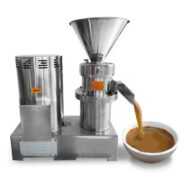

Why should I buy a colloid mill grinder?A colloid mill grinder machine is an advanced colloid mill capable of finely processing fluid and semi-fluid materials with high efficiency. It combines the functions of several equipment—such as a homogenizer, ball mill, three-roll mill, shear, and blender—allowing for ultrafine grinding, dispersion, emulsification, homogenization, and thorough mixing in one machine. Its ability to produce particles between 2 to 50 microns with over 95% uniformity ensures high-quality, smooth sauces and pastes. Suitable for industries like food, pharmaceuticals, and chemicals, this colloid mill grinder machine can replace or surpass traditional processing equipment like stone mills, sand mills, and homogenizers, significantly improving production efficiency and product consistency. How does a colloid mill grinder machine work?The colloid mill grinder machine operates using the principle of high-speed shearing. A motor drives a rotating rotor that works in conjunction with a stationary stator. When the material is fed into the machine, it passes through the narrow gap between the rotor and stator. The intense shear forces, friction, and vibrations generated by the high-speed rotation rapidly break down the particles, resulting in a fine, uniform paste. The gap can be adjusted to achieve the desired particle size, typically between 20-60 microns, with over 95% homogeneity. This design allows for efficient grinding, emulsifying, and mixing, making it ideal for producing high-quality sauces, pastes, and similar products in the food, chemical, and pharmaceutical industries. What are the main applications of the colloid mill grinder Machine?The colloid mill grinder is a highly adaptable and efficient equipment essential for producing smooth, high-quality products across diverse industries, including food, chemicals, pharmaceuticals, construction, and more. Its versatile design and wide range of applications make it an invaluable tool for achieving fine, uniform textures and advanced processing requirements. – Food Industry: Used to process dairy products, chocolate, soybean paste, jam, peanut butter, cream drinks, chili sauce, sesame, fruit tea, ice cream, mooncake fillings, soy milk, and other food and beverage items, ensuring smooth and uniform textures.

– Chemical Industry: Applied in manufacturing pigments, dyes, emulsified asphalt, lubricants, catalysts, paints, coatings, plastics, rubber, and synthetic materials.

– Pharmaceutical Industry: Suitable for finely processing syrups, ointments, royal jelly, pollen, nutrient solutions, traditional Chinese medicines, vaccines, and various medical formulations.

– Daily Chemicals: Used in producing toothpaste, shampoos, cosmetics, soaps, balms, and other personal care and household products.

– Construction Industry: Employed for producing interior and exterior wall coatings, waterproofing, anti-corrosion coatings, ceramic glazes, and spray coatings.

– Other Industries: Applied in plastics, textiles, papermaking, coal flotation agents, rare earth metals, nanomaterials, and advanced military materials. What are the structural features and operating precautions of a colloid mill grinder?Colloid mill grinder machines are typically constructed from stainless steel, semi-stainless steel, or carbon steel, featuring a compact and efficient design that is easy to operate and maintain. The main components include the housing, stator, rotor, adjustment mechanism, motor, and cooling system. A key feature is the use of high-quality stainless steel for the stator and rotor, providing excellent corrosion and wear resistance for long-term stable operation. The gap between the stator and rotor is adjustable, allowing precise control over the grinding fineness to suit different materials. Material selection for these parts can be tailored based on the specific characteristics of the processed material to optimize performance. Operating precautions include:

– Maintaining appropriate speed to prevent excessive shearing, which can cause nutrient loss or overheating.

– Regular cleaning and maintenance to ensure consistent quality and prolong equipment lifespan.

– Ensuring a proper seal to prevent contamination.

– Selecting the appropriate model and configuration based on production requirements for optimal efficiency and safety. What are the differences between vertical and split-type colloid mill grinder?The colloid mill grinder is available in both vertical and horizontal configurations, made from stainless steel, semi-stainless steel, or carbon steel to suit various processing needs. – Vertical sauce paste grinding machine:

Typically designed as a single, integrated unit, offering straightforward operation. – Split-Type sauce paste grinding machine:

Designed for easy disassembly, which simplifies maintenance and cleaning. They provide superior sealing capabilities; a tighter seal ensures better container integrity and reduces the risk of damage. Poor sealing can lead to contamination or moisture ingress, potentially damaging the motor or reducer. What is the difference between circulation tubes and square outlets on a colloid mill grinder?– Circulation Tubes: Designed for bottom-of-the-line products that require reflux grinding to achieve finer consistency, such as peanuts and chili peppers. This setup allows the material to circulate repeatedly for thorough processing. – Square Outlets: Suitable for medium-to-high concentration products that do not need reflux grinding, also including items like peanuts and chili peppers. This configuration is typically used for more direct, one-pass processing. | |

Leave a Reply