Why should I invest in a gas continuous fryer for my food production facility?

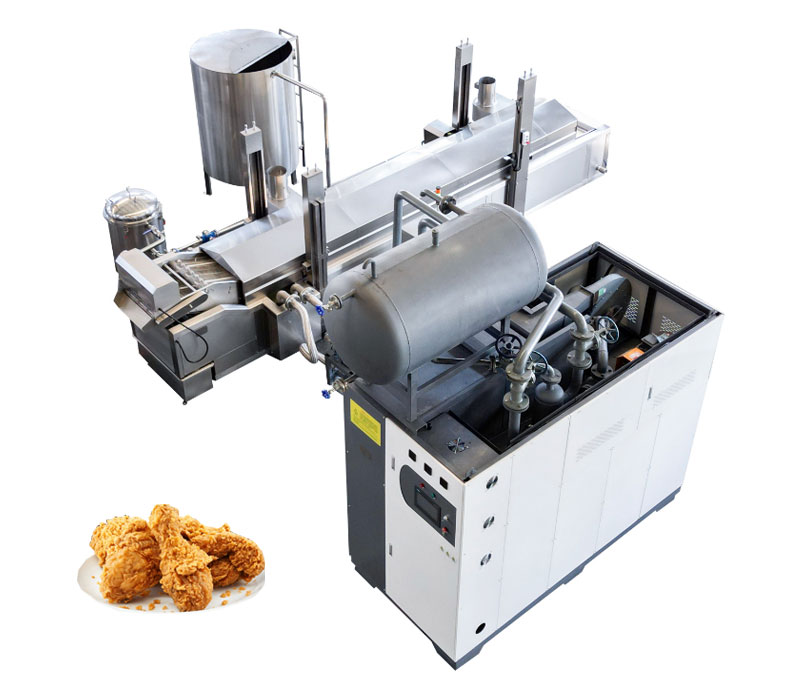

The advanced heat management system in the gas continuous fryer creates a stable frying environment, ensuring uniform color, texture, and coating adhesion across all products. Its automatic oil replenishment, circulation, and filtration systems significantly extend the oil’s service life—up to ten times—while maintaining oil cleanliness and safety. The machine’s energy-efficient gas heating options (either a heat exchanger or thermal oil furnace) combined with hygienic stainless steel construction make it ideal for high-capacity, continuous, and safe frying operations. Its multi-zone heating and self-cleaning features support consistent quality, efficiency, and safety, making it suitable for restaurants, snack factories, large food processing plants, hotels, and industrial kitchens.

Investing in this advanced gas continuous fryer offers several strategic advantages:

Customizable & Versatile: The mesh belts can be tailored for different food products, and the machine supports various heating methods (electric, gas), making it adaptable to your specific needs.

High Capacity & Continuous Production: Designed for large-scale frying, it enables high-output, continuous operation, perfect for meeting large order demands and increasing overall productivity.

Superior Product Quality: Equipped with multiple mesh belts (scraper, conveyor, pressure) and automatic temperature control (±1°C accuracy), it ensures even frying, consistent color, and taste. The advanced heat management system creates a stable frying climate for uniformly fried products with excellent coating adhesion. Automatic slag removal and circulating oil filtration help maintain clean frying oil, preventing excessive acidification and ensuring top-quality products like French fries, donuts, and chips.

Energy Efficiency & Cost Savings: Utilizing large-area electric heating, the machine heats quickly and efficiently, reducing energy consumption. It can save up to 50% of cooking oil compared to traditional fryers, lowering operational costs.

Automation & Ease of Operation: Features such as automatic oil replenishment, discharging, feeding, and adjustable frying times (from 20 seconds to 15 minutes) require only one operator, streamlining workflow and reducing labor costs.

Hygiene & Durability: Made of full stainless steel 304, it meets strict hygiene standards, is waterproof with good sealing for easy cleaning, and has a long service life. Its modular electric control cabinet allows safe, convenient operation and disassembly during transportation.

Safety & Reliability: Multiple safety devices, alarms, and automatic temperature controls ensure safe operation, preventing accidents and equipment damage. The machine operates smoothly and quietly without noise.

In summary, this high-automation, energy-efficient, and hygienic gas continuous fryer maximizes productivity, produces consistently high-quality fried foods, reduces operational costs, and provides a strong return on investment—making it an essential asset for professional food manufacturing businesses.

What kinds of food products can be processed using the gas continuous fryer?

The gas continuous fryer is a highly versatile, large-scale food processing equipment suitable for a wide range of fried foods across the food industry. It can efficiently fry:

Meat and poultry: chicken patties, nuggets, chicken drumsticks, chicken cutlets, braised pork, meatballs, fatty meats, pork trotters, beef jerky, chicken chops

Seafood: fish, shrimp, squid rings, fried fish products

Nuts and legumes: peanuts, broad beans, sunflower seeds, chickpeas

Vegetables: vegetables, rice snacks, dim sum, rice crackers

Snack foods: potato chips, banana chips, puffed foods, caramel snacks

Dough and bakery items: dough sticks, meat pies, fried dough, fried twist, dough, rice-based snacks

Other: seafood, vegetables, fried rice skin, aquatic products, pasta, and more

With the gas continuous fryer, you can fry products faster, save labor, produce brighter-colored nuggets, and reduce oil consumption, making it an efficient and reliable choice for large-scale fried food production.

Is it safe to operate the gas continuous fryer?

Yes, the gas continuous fryer is designed with multiple safety features to ensure safe operation. The gas thermal oil furnace is equipped with a burner and a solenoid valve that opens when gas and air are properly mixed; if no gas is detected, an automatic alarm is triggered. The burner also has a one-way check valve to prevent gas from escaping backward, further enhancing safety. The fryer is heated by a thermal oil medium from the thermal oil furnace, which enters the bottom of the fryer through a pipeline to heat the edible oil. This method is very safe and does not interfere with the fryer’s cleaning and filtration processes. Additional safety measures include automatic fire extinguishing devices (CO₂ spray), emergency stop switches, over-temperature alarms, sensors that cut off power if abnormal conditions occur, and protections against short circuits, overloads, and grounding issues. The equipment’s design also features safety bars, liftable components for easy cleaning, residue discharge systems, and safety alarms to prevent accidents during operation. When operated according to safety protocols and maintained properly, the gas continuous fryer offers a safe and reliable frying environment

How do I install and start up the thermal oil furnace for the gas continuous fryer?

Installing and starting up the thermal oil furnace involves several key steps to ensure safe and proper operation:

Circuit Check:

Begin by inspecting all wiring connections and tightening bolts to prevent issues caused by transport vibrations. Confirm that the power lock and emergency stop button on the control panel are in the “on” position. Turn on the power and verify that all components in the control panel and cabinet are functioning normally. Manually operate the circulation pump through the touch screen to check its forward (clockwise) and reverse rotation; if the rotation is incorrect, adjust the wiring accordingly. Similarly, test the blower fan impeller to ensure correct rotation; incorrect rotation will result in no wind pressure at the flue gas outlet. Adjust the blower wiring if necessary. Note that since the system is not yet heated or gas-connected, an alarm may sound initially—this is normal. Set the initial working temperature on the touch screen to 90°C.

Gas Connection and Check:

Turn on the gas supply and observe the pressure gauge to ensure proper pressure within the appropriate range. Use the supplied gas leak detector to inspect all pipeline joints—both from the gas interface to the burner inlet for pipeline natural gas, or from the cylinder outlet valve to the burner for liquefied gas. Address any leaks before proceeding.

Filling Heat Transfer Oil:

Check that all valves in the heat transfer oil circulation system are correctly positioned—except for the internal circulation valve, which should be closed, all others should be open. Use a manual or electric pump to fill heat transfer oil through the expansion tank’s filling/exhaust port, ensuring the initial amount does not exceed 1/4 of the tank’s liquid level gauge. Turn on the circulation pump via the touch screen and monitor the oil level; add oil intermittently to maintain the level at about 1/4 of the gauge. Stop adding oil once the pressure gauge stabilizes. During this process, inspect the piping system for leaks and address any issues promptly.

Following these steps ensures a safe, efficient, and correct installation of the thermal oil furnace for your gas continuous fryer. Always adhere to safety protocols and consult the manufacturer’s manual for detailed instructions.

How do I start the thermal oil furnace for the gas continuous fryer for the first time?

To start the thermal oil furnace, follow these steps:

1. Press the power button on the touch screen to turn on the system.

2. The automatic 20-second pre-purge will begin, during which you should observe the fan startup and monitor the wind pressure gauge parameters.

3. After the pre-purge, the auxiliary heating will automatically ignite, and the main heating will switch on after approximately 15 seconds. The program controller button will turn green, indicating successful ignition. You can also verify ignition through the fire viewing hole on the burner.

4. If ignition fails, the buzzer will alarm, and the system will automatically enter a 20-second post-purge, with the program controller button turning red.

5. Once the post-purge is complete, the system will automatically attempt to ignite again. Note that initial ignition may be weak due to residual air in the gas pipeline, which is normal.

6. If ignition fails repeatedly, it could be due to incorrect opening of the main or auxiliary heating control valves. In this case, contact our technical support hotline for assistance.

After successful ignition, the system will enter the normal working state, allowing the heat transfer oil to be heated and dehydrated as needed.

How do I adjust the combustion in the gas continuous fryer thermal oil furnace during operation to match the heat load?

Proper combustion adjustment is vital for efficient, safe, and stable operation of the gas continuous fryer thermal oil furnace. During actual operation, it’s often necessary to modify the output of the furnace based on the heat demand of the equipment. This adjustment can be performed by regulating both the gas flow and air volume in the combustion system:

– Gas Flow Adjustment:

The heater is equipped with two valves featuring scales and handles:

– The vertical valve controls the main heating gas flow.

– The horizontal valve controls the auxiliary heating gas flow.

Turning each handle adjusts the pointer to the corresponding scale, thereby regulating the gas volume supplied to the main and auxiliary burners.

– Adjusting Heating Power:

The auxiliary heating size can be changed by adjusting the auxiliary heating regulating valve and inverter parameter 1.

The main heating size can be adjusted by controlling the main heating regulating valve and inverter parameter 2.

– Combustion Control Steps:

- Use the handles on the valves to set the gas flow to the desired levels based on the load.

- Adjust the inverter parameters accordingly to fine-tune the heating output.

- During operation, monitor the combustion status, ensuring stable flame and no abnormal noise or fluctuations.

– Heating and Dehydration Procedure:

Before regular operation, perform heating and dehydration of the thermal oil:

– Open the circulation pump manually via the touch screen and circulate cold thermal oil for about 20 minutes.

– Gradually increase the working temperature in steps (starting from 80°C, then 90°C, and increasing by 5°C each time), observing the oil pressure gauge and liquid level.

– Maintain stable pressure and temperature, and control the exhaust volume—especially in the 105–130°C temperature range—to prevent oil and steam from spraying out.

– When the outlet temperature reaches approximately 200°C, with no steam during exhaust and stable oil pressure, dehydration is complete. Check the oil level after cooling and replenish if below 1/5 of the display.

Safety Note:

Always carefully monitor combustion parameters to prevent over-oxidation or incomplete combustion. If you encounter persistent ignition issues or abnormal combustion, contact technical support for adjustments.

How should I operate and maintain the thermal oil furnace for the gas continuous fryer to ensure safe and efficient performance?

Proper operation and regular maintenance are crucial for the safe, stable, and efficient functioning of the thermal oil furnace. The process includes understanding the automatic temperature control principle, routine checks, troubleshooting common faults, and safety precautions:

– Automatic Temperature Control:

The furnace automatically adjusts heating output by regulating the main and auxiliary gas burners via control valves and inverter parameters, based on the heat transfer oil temperature. The set temperature is typically slightly higher than the required heat-using equipment temperature to compensate for heat loss and instrument error. The system maintains a fluctuation of ±3–5°C, with the temperature difference between outlet and return oil around 15–20°C.

– Operational Guidelines:

Assign trained personnel for management. After 7 days of operation, tighten all joints, check for leaks, and ensure the circulation system functions correctly. Regularly monitor system parameters such as air pressure, wind pressure, and oil pressure; address abnormalities immediately. Before stopping, set the pump temperature to 90°C to prevent coking, and always close the main gas pipeline valve when shutting down. Keep the heater clean, inspect pipelines for leaks, and perform periodic replacement of heat transfer oil based on condition.

– Routine Maintenance:

– Tighten flange bolts and check for leaks weekly.

– Clean filters and remove dust regularly.

– Check and adjust gas and air flow using the control valves and inverter parameters.

– Inspect the ignition system, solenoid valves, and ion probes periodically.

– Ensure safety devices like alarms, emergency stop buttons, and over-temperature protections are functional.

– Troubleshooting Common Faults:

– Fan or pump failures often relate to inverter faults or wiring issues—check and replace damaged components.

– Ignition failures can result from improper gas flow, electrode faults, or flame detection problems—adjust valves, replace electrodes, and verify spark.

– Flameouts or abnormal shutdowns may be caused by improper gas/air pressure, solenoid failure, or coking—adjust pressure regulators, inspect solenoid valves, and clean pipelines.

– Over-temperature alarms or large temperature differences indicate overloads or system blockages—reduce load, clean pipelines, or replace faulty sensors.

Safety Reminder:

Always operate within the specified parameters, regularly inspect for leaks, and ensure all safety devices are active. For persistent or complex issues, contact technical support promptly.

Leave a Reply