What products can this gas grill marker machine grill?

VERFoodSolutions Gas grill marker is professionally developed by our company to achieve surface carbonization and branding of meat steaks, fish steaks, chicken steaks, meat patties and other products in food factories. It can quickly carbonize the surface cortex of various steak products at high temperatures, increasing the number of products. It can produce popular hamburger patties, meat steaks, fish steaks, chicken steak pieces, fish-flavored hamburger patties, potato cakes, pumpkin cakes and other products on the market. It is an ideal meat (vegetable) carbonization for fast food restaurants, distribution centers and food factories.

Gas grill marker is suitable for the grilling of different kinds of product such as steaks, burger, sausage, chicken breast, fish filler, zucchini, tofu, etc.

Why I should order one gas grill maker machine?

VERFoodSolutions Gas grill marker machine has been professionally developed by our company for the purpose of achieving surface carbonization and branding of meat steaks, fish steaks, chicken steaks, meat patties, and other food products in food factories. This machine is capable of quickly carbonizing the surface cortex of various steak products at high temperatures, thereby increasing productivity. It is able to produce popular items such as hamburger patties, meat steaks, fish steaks, chicken steak pieces, fish-flavored hamburger patties, potato cakes, pumpkin cakes, and other products commonly found in the market. The grill marker machine is an ideal solution for achieving meat or vegetable carbonization in fast food restaurants, distribution centers, and food factories.

How to choose the right gas grill marker?

In order to recommend the most suitable grill marker for your needs, please provide us with the detail products dimension(length*width*thickness), each product weight, required capacity(how many kgs per hour), grill heating power, grill width, grill mark gap distance etc.

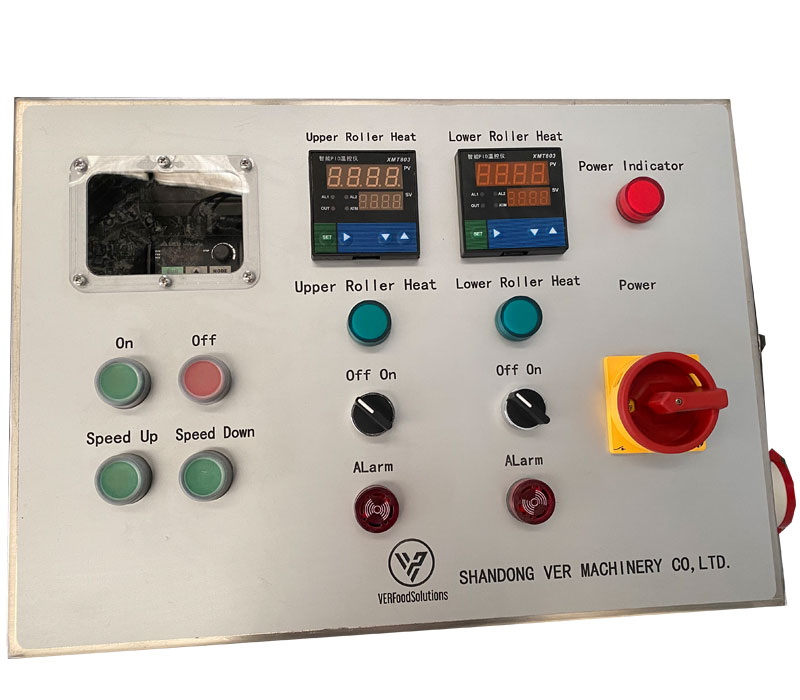

How to operating gas grill marker machine?

To ensure optimal operation of your gas grill marker machine, follow these steps:

Raw Material Loading:

Load boneless and thawed raw meat within the specified size range of 5-35mm thickness to achieve the ideal searing effect. Ensure that the feeding speed is equal to or less than the machine’s production capacity, and aim for a uniform, continuous feed to prevent overloading the machine.

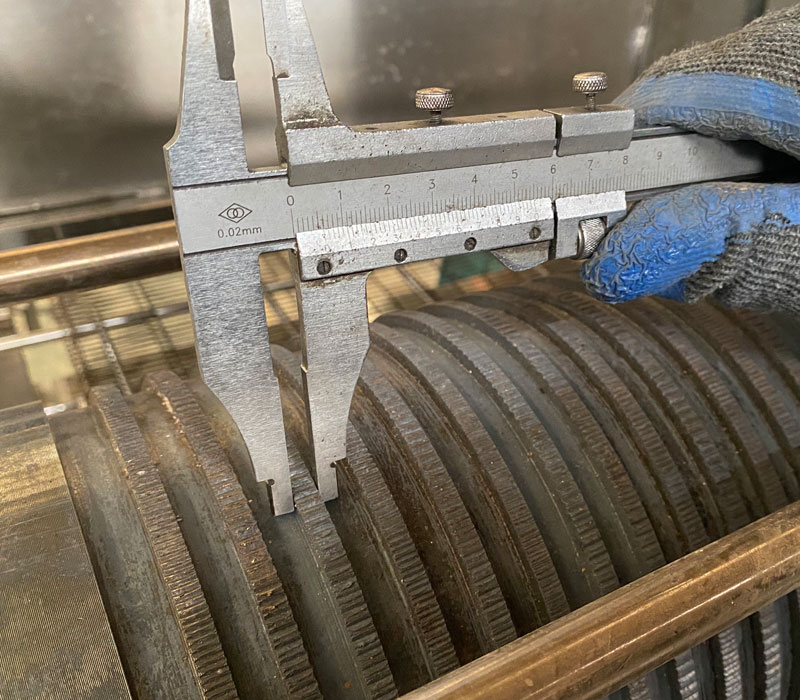

Heating Roller Distance Adjustment:

Adjust the distance between the rollers and the searing depth according to your production process. This will help achieve a flat, moderate, and uniform searing for the best results.

Feeding Process:

Place the raw materials on the mesh belt one by one. The mesh belt will convey them to the searing point; ensure quality through inspection after searing to meet process requirements. To enhance searing quality and efficiency, keep the feeding speed as close to the machine’s production capacity as possible.

By following these steps, you will improve the searing quality and ensure effective operation of your grill marker machine.

What is the warranty for the gas grill maker machine?

-We will send you all detail operation videos, including how to operate and maintenance this machine.

-We provide 12 months warranty time once delivery for gas grill marker.

-With machine delivering, we will send you full set of spare parts with the machine free for 5 years using.

Leave a Reply