Fish Slicing Machine

Main Benefits

- Simple operation requires only one skilled operator

- Improves food safety through minimal human contact

- Adaptable to various fish sizes for versatile processing

- Minimizes operator fatigue, reducing workplace injury risks

- Increases production efficiency, saving time and labor costs

- Enables accurate portion control for better cost management

- Streamlines production line for smoother workflow operations

- Provides customized cutting options for diverse market needs

- Lowers maintenance costs with durable, long-lasting components

- Enhances product traceability for improved quality control

- Facilitates compliance with food safety regulations and standards

- Fast cutting speed preserves freshness of fish products

Overview

Our Automatic fish slicing machine is expertly crafted to handle various types of fish, including salmon, tilapia, and herring, transforming them into uniform, high-quality fillets. With its unique design that simulates manual slicing, this machine achieves consistently precise thickness and is customization to your specific requirements. This feature enables you to serve your dishes with the visual appeal and freshness that discerning customers expect.

Speed and efficiency are hallmarks of this innovative machine, capable of processing between 150kg to 250kg of fish per hour. With slicing capabilities that reach an impressive 280 to 600 slices per minute, you can keep up with the demands of a busy kitchen or food operation, ensuring that your staff spends less time slicing and more time on food preparation and customer service.The machine offers adjustable slicing angles of 25°, 30°, and even 45°, providing versatility in presentation according to your culinary needs. The fish fillets produced have a smooth cut surface, free of any unsightly frayed edges that can detract from your culinary creations.

Videos

Features

- Available in single-bin and double-bin configurations for efficiency.

- Single-bin processes 100kgs per hour; double-bin processes 200kgs per hour.

- Adjustable cutting thickness from 1.8mm to 10mm without interrupting machine operation.

- Customization slope angles (25°, 30°, 35°, 40°, 45°).

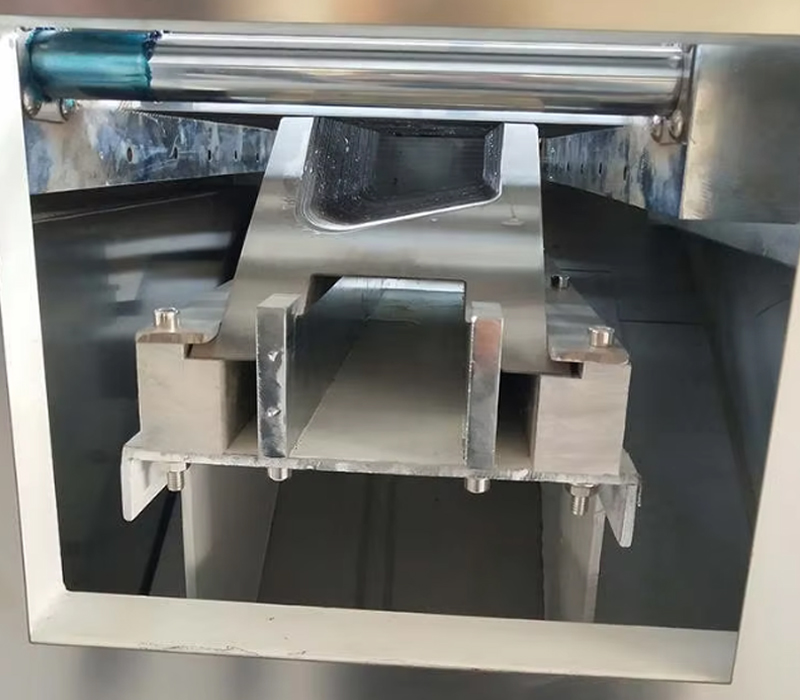

- High-speed rotating circular blades for precise cutting.

- Suitable for fresh and frozen fish of various sizes.

- Easy-to-clean removable components for maintenance.

- Compact design with customization machine dimensions.

- Compatible with multiple fish species and seafood types.

- Imported disposable blades eliminate need for sharpening

Specifications

| Model | FSM-S | FSM-D |

| Bins Number (Pcs) | 1 | 2 |

| Capacity (Pcs/Mini) | 280 | 560 |

| Output (Kgs/h) | 100 | 200 |

| Voltage(V) | 110/220/240/380/415 | 110/220/240/380/415 |

| Main Motor Power(Kw) | 1.5 | 1.5 |

| Lifting Motor Power(Kw) | 0.25 | 0.25 |

| Customized Thickness(mm) | 1.5-10 | 1.5-10 |

| Customized Cutting Angle | 25, 30, 35,40, 45 Degree | 25, 30, 35,40, 45 Degree |

| Machine Weight(Kg) | 200 | 220 |

| Dimension(mm) | 830*730*850 | 830*880*850 |

FAQ

Why should I use a fish slicing machine to cut fish slices?

Fish fillet slice are popular among consumers for their rich protein content and delicious flavor. However, processing fish for fillets can be challenging, especially in achieving consistent thickness. Manual cutting often leads to uneven fillets and increases the risk of worker injuries.

Using an automatic fish filleting machine effectively addresses these challenges. Here are key benefits:

Consistency: The machine produces uniformly sliced fish fillets, enhancing presentation and cooking quality.

Efficiency: Automated slicing speeds up the filleting process, boosting production rates while reducing labor time.

Safety: Minimizing manual handling lowers the risk of cuts and injuries associated with traditional methods.

Quality Control: The machine maintains precision, ensuring better overall product quality.

In summary, employing a fish fillet machine streamlines the processing of fish, improving safety and consistency, making it an excellent choice for fish processing operations.

What types of products can a fish slicing machine process?

Our fish slicing machine is designed to efficiently slice various types of seafood, including fish like blackbelly rosefish, salmon, trout, gurnard, and others. It can also process pork belly, pork liver, and squid. This filleting machine is ideal for catering businesses such as hot pot shops, boiled fish restaurants, pickled cabbage fish establishments, office canteens, hotels, and other food service providers. Its versatility enables it to handle fresh or completely defrosted fish without bone spurs, making it an essential tool for chefs and food preparers looking for consistent and high-quality cuts in their meals.

What is the process for using the fish slicing machine?

The operation of the fish slicing machine is straightforward and efficient. Below are the steps involved:

1. Preparation: Start by thoroughly cleaning and scaling the fish. This is essential to ensure the fish is suitable for slicing and free from any contaminants.

2. Head Removal: Next, cut off the fish head. This step is important as the head typically contains more bones, which can hinder the slicing process.

3. Cut the Fish in Half: Slice the fish down the middle to divide it into two parts, ensuring that you remove any remaining fish bones that may interfere with the slicing.

4. Feeding the Fish into the Machine: Place the prepared fish meat onto the designated fish feeding tray. The tray is designed for automatic feeding, allowing the fish to be guided smoothly into the machine.

5. Automatic Slicing: Once the fish enters the machine, the feeding tray will gradually rise. Inside the machine, a cross-cutting blade operates on a horizontal plane. As the tray lifts, the fish meat gradually comes into contact with the blade, allowing the automatic fish slicing machine to cut the whole fish into even, uniform slices continuously.

6. Collecting the Slices: After the slicing process, the finished slices will be available for retrieval using the tray, which allows for easy collection of the uniformly cut fish fillets

What are the safety and maintenance precautions for operating the fish slicing machine?

To ensure safe and effective operation of the fish slicing machine, please follow these essential safety and maintenance precautions:

1. Power Supply Check: Before starting the machine, confirm that the power supply is stable and functioning properly.

2. Mechanical Inspection: Inspect the machine to ensure there are no loose parts. Tighten any loose screws or components to prevent operational issues.

3. Hazard Assessment: Ensure that there are no flammable or explosive materials in the vicinity of the machine during operation. Safety first!

4. Injury Prevention: Always be mindful of safety while the machine is running. Avoid placing hands or other objects near rotating parts and cutting blades.

5. Material Restrictions: It is strictly forbidden to use the machine for cutting frozen fish, bone-in fish, or other meats, as this can damage the equipment and compromise safety.

6. Pre-Operation Checks: Before starting or troubleshooting the machine, always check that the nuts and bolts of all parts are secure to prevent malfunctions.

7. Emergency Protocol: Do not reach deep into the machine while it is operating. If clothing or limbs become caught, immediately press the emergency stop button.

8. Sign Out for Repairs: Perform any repairs or inspections only after turning off the machine. Never attempt to clean or service the machine while it is powered on to avoid accidents.

9. Lubrication: Before each use, check the slide rails for lubrication. Ensure that the cutter and screws are tight and add oil to all necessary parts to maintain optimal machine performance.

10. Stable Installation: Position the fish slicer on a stable surface to prevent tipping or movement during operation.

11. Feed Inlet Maintenance: Ensure that the feed inlet is free from any obstructions before connecting the power supply and grounding wire, following the power supply instructions on the machine’s label.

12. Post-Usage Care: After using the machine, always turn off the power to facilitate cleaning. Be cautious around sharp components such as blades and knives when disassembling for maintenance.

To ensure the longevity of a fish slicing machine, regular maintenance is essential. This includes cleaning the machine after each use to prevent cross-contamination and buildup of residue. Operators should also inspect and sharpen the blades regularly to maintain cutting efficiency. Additionally, periodic checks on mechanical parts, such as motors and belts, should be performed to identify any wear or malfunction early. Following the VERFOODSOLUTIONS’s maintenance guidelines will help keep the machine in optimal working condition.