What if I need to produce other shapes products on this gua bao bun machine?

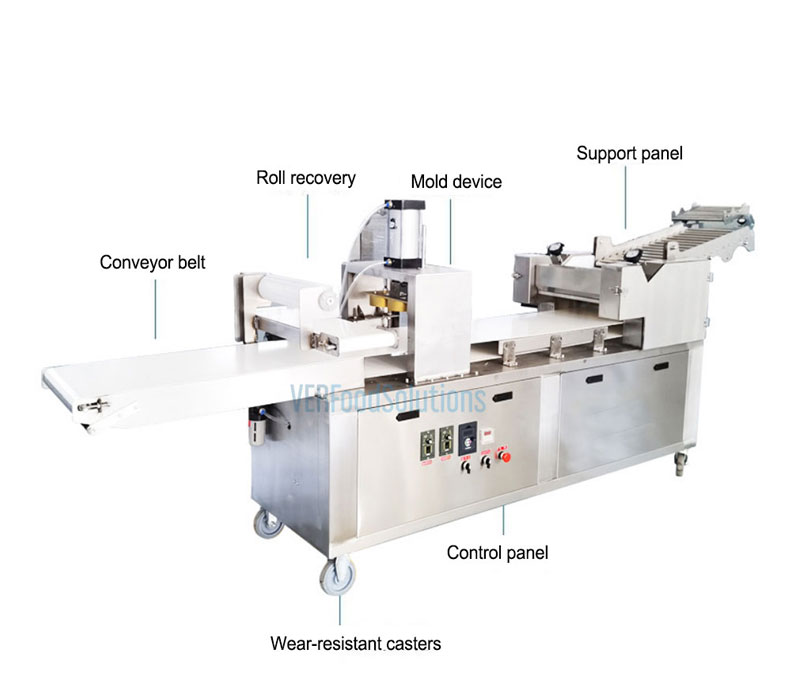

The gua bao bun machine is designed with interchangeable molds. The forming molds can be easily replaced to accommodate different product shapes and sizes. The replacement process is simple and user-friendly:

- The mold can be removed by unscrewing a few screws.

- Once the screws are removed, the current mold can be lifted out.

- The new mold can then be placed in the designated area.

- Secure the new mold by screwing it back into place.

This feature allows for versatility in production, enabling you to create various types of buns and pastries with the same machine. The straightforward replacement process ensures minimal downtime during product changeovers.

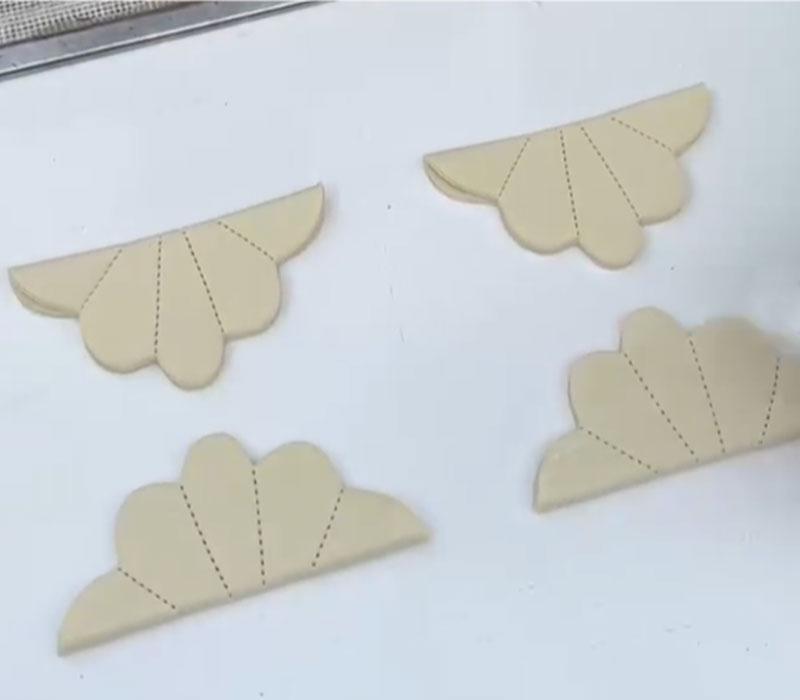

What kind of products can the gua bau bun machine make?

The gua bau bun machine is highly versatile and can produce a wide range of products by utilizing different customizable molds. Some of the products this machine can make include:

- Gua bau buns

- Bau bun

- Taiwanese burger bun

- Lotus leaf Steam Bun

- Bubai steamed buns

- Moon steamed buns

- Pizza Bun

9.Pita Tortilla Bread

- Naan

By simply changing the molds, you can easily switch between these different product types. This flexibility allows you to diversify your product offerings and cater to various customer preferences without the need for multiple machines. The ability to customize mold shapes further expands the potential for creating unique and innovative products.

Can I easily switch between single-sided and double-sided products using the gua bau bun machine?

Yes, our gun bau bun machine is designed for flexibility. It features a versatile stacking device that can be adjusted according to your needs.

– For double-sided products, simply lower the stacking device. The integrated oil brush helps prevent the two sides from sticking together during the cooking process.

– If you want to produce single-layer or single-sided products, you can easily raise the stacking device. This adjustment allows the machine to efficiently create single-sided products.

In summary, our gua bau bun machine allows for seamless conversion between single-sided, double-sided, and single-layer products with minimal effort.

Can the size and thickness of the bun be customized with the gua bau bun machine?

Absolutely! The gua bau bun machine offers extensive customization options for product size and thickness.

– Mold Replacement: You can easily replace and customize the molds to achieve various sizes for your products.

– Thickness Adjustment:The pressing pin and upper adjustment handwheel allow you to modify the thickness of your products to meet your specific requirements.

– Pattern Customization:Additionally, the machine enables you to customize patterns, allowing you to create distinctive products by using different designs.

In summary, the gua bau bun machine is highly adaptable, making it easy to create customized products in various sizes and with unique patterns.

Does the gua bau bun machine have a waste dough recycling function?

Yes, the gun bun machine features a waste dough recycling function. After the product is made, any remaining unused dough is recycled through the noodle pressing roller, effectively reducing waste and saving on production costs. Additionally, you can easily adjust the recycling speed of the waste dough roller using the knob on the control panel.

Can the production speed be adjusted for the gua bau bun machine?

Yes, the gua bau bun machine is equipped with control panel buttons that allow you to manage the overall machine functions, including the cutter switch and cutter speed. Additionally, you can adjust the noodle pressing time and speed, the forming switch, and the skin-returning conveyor belt switch. By coordinating these functions, the machine can achieve an output range of 1,200 to 7,200 units per hour.

Can I use the gua bun machine in conjunction with other equipment?

Absolutely! The gun bun machinefeatures a conveyor belt for production, enabling it to be connected with other equipment such as a pancake maker, plate setting machine, or rice steaming cabinet. This integration allows for continuous production and increased production capacity.

Leave a Reply