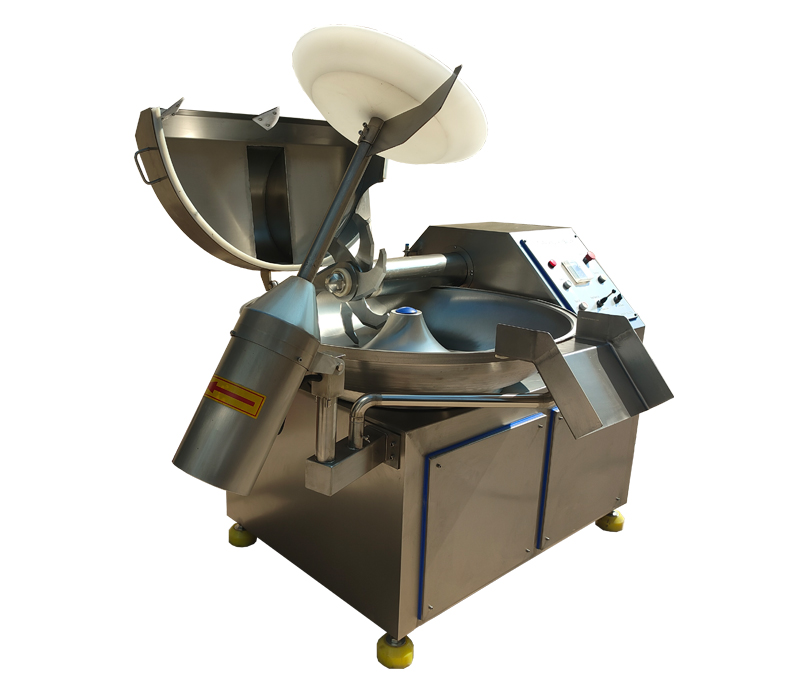

Why should we order one industrial bowl chopper?

VER meat bowl cutter is one important machine in the meat preparation, the high-speed rotating chopping knife can chop and mix the raw meat into fine mince, meat, fruits and vegetables, seafood. The high-speed rotation of the chopper can shorten the mixing time, reduce the heat generation of the material, and maintain the color, elasticity, yield and shelf life of the filling, this machine is an ideal meat processing machine for hotels, restaurants, canteens, meat processing plants and other units.

What is the working principle for the industrial bowl chopper?

VER meat bowl cutter could chop the meat and auxiliary materials into meat filling or meat puree, and stir the auxiliary materials, borneol, water together with the meat filling or meat pieces evenly by chopping action of the high-speed rotation of the cutter.

The machine motor makes the worm drive the turbine through the V-belt, and the meat cutting plate rotates in one direction through the ratchet mechanism. When the meat is chopped, the shaft is lifted, and when the material is to be discharged, the control circuit is put down and the control circuit is turned on, and the discharge turntable shaft returns to the position.

Is it safe to operate this industrial bowl chopper?

It is very safe to operate this meat bowl chopper.

-The meat bowl cutter has large starting torque, high insulation and heat resistance level, good overload protection performance, and you could turn on and turn off the machine frequently.

-The machine cover is equipped with a safety device to ensure the operator safety.

When the machine is working, you could cover the blade assembly to prevent the material from splashing. The knife cover is interlocked with the drive motor of the chopper shaft. Only when the cover is closed, the knife shaft motor can be started.

Is the industrial bowl chopper working stable?

The whole meat bowl chopper is made of full stainless 304, accordance with hygiene standards

All the spare parts for this bowl chopper are famous brand all over the world, below is the spare parts list& its brands:

-Siemens Motor or Japan SANYO servo motor drive as drive system optional

-Germany Busch vacuum pump

-USA EMERSON or Denmark DANFOSS frequency control technology

-Sweden SKF bearings

-Swiss ABB electrics

-Japan Mitsubishi PLC optional

-Swiss ABB water-proof button

What is the preparations for the industrial bowl chopper working?

-Fix the device smoothly, pay attention to the four corners and the ground firmly touched, and then connect the power supply. Before testing the machine, check whether there is any looseness during transportation, and then test the machine after confirming it is correct. The equipment shell must be grounded reliably to ensure the safety.

– First jog the discharge switch and observe the direction of rotation. If the direction of rotation is correct, the chopper can be turned on, and the machine can be turned on only when the chopper rotates.

-Before testing the machine, jog the feeder switch or the bowl switch (turn the bowl counterclockwise).

Why should I order one industrial bowl chopper rather than one meat grinding machine?

VER Industrial bowl chopper is an important meat processing machine for emulsifying pork skin, chicken skin and minced meat that could not be minced by meat grinding machine. The meat bowl chopper machine could cut the fiber in the meat at two speeds to increase the product taste.

The knife speed, pot speed, and the gap between the chopper and the rotating pot are properly combined, so that the meat temperature rise is small, and the chopping time is short, especially due to the emulsification treatment, the fineness of the sausage products and the elasticity is greatly enhanced, which greatly improves the emulsification effect, elasticity and fineness of meat products.

Leave a Reply