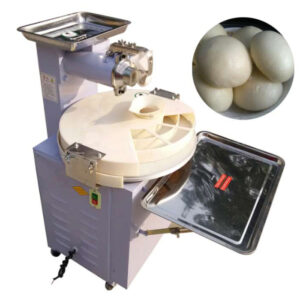

What is the application for the dough rounder machine?

The dough rounder machine is an essential piece of equipment in commercial baking and food processing industries. Its primary application is to automatically shape and round different types of dough into uniform balls or rounds, which is a crucial step in producing high-quality baked goods. This machine is widely used in bakeries, pizzerias, central kitchens, food processing plants, restaurant chains, baking education institutions, and R&D laboratories. Its versatility allows it to handle various dough products, including bread dough, pizza dough, pita bread, rolls, donuts, cookies, energy balls, and other soft or round dough items.

Why should I buy a dough rounder machine?

Investing in a dough divider and rounding machine offers significant benefits that can transform your bakery or food production operation. This equipment automates the portioning and shaping of dough, drastically reducing manual labor and increasing overall production speed. Its ability to handle various dough types—including medium-soft, oily, or non-oily doughs with 45%-70% moisture content—makes it highly adaptable for different recipes and product demands. The machine ensures each dough piece has a consistent weight and a perfect round shape, which leads to uniform baking results, improved product appearance, and higher quality standards.

The machine’s design includes conical components, guide rails, and spiral tracks that mimic manual rolling, guaranteeing uniformity in shape and size. It can operate continuously for up to 12 hours, making it ideal for high-volume bakeries, chain stores, and industrial food production facilities. Its construction from high-quality stainless steel, with optional nano-ceramic or Teflon coatings, ensures durability, easy cleaning, and compliance with food safety standards. The equipment is also highly flexible—adjustable for different dough sizes and weights—and can be integrated with other machinery like dividers, proofers, and shapers to form a fully automated production line. Overall, this machine enhances efficiency, ensures consistent product quality, reduces labor costs, and supports the scalability of your business—making it a valuable investment for modern bakeries aiming for high productivity and top-quality output.

What types of dough can this dough rounder machine handle?

The dough rounder machine is designed with versatility in mind, capable of handling a wide variety of dough types commonly used in commercial bakeries and food processing facilities. It can efficiently process medium-soft doughs, whether they are oily or non-oily, making it suitable for a broad range of recipes. The machine is particularly effective for dough with a moisture content between 45% and 70%, which includes most bread, pizza, pita, roll, and donut doughs. Its gentle yet precise rounding process ensures that the dough maintains its gluten structure without damage, resulting in uniform, high-quality dough balls.

This flexibility allows the machine to be used for different products, from soft, fluffy dinner bread to firmer, more elastic doughs used in artisanal bread or specialty baked goods. It can handle various ingredients, including those with high hydration levels, making it ideal for diverse baking needs. Additionally, the machine’s design prevents sticking and facilitates easy cleaning, supporting hygienic operations across different dough types. Whether used independently or integrated into a production line, this machine can meet the demands of many baking scenarios, ensuring consistent, perfectly rounded dough pieces every time.

Why does this dough rounding machine consistently produce dough balls with uniform weight and perfect round shape?

This dough rounding machine is engineered with advanced features that ensure high precision and consistency in shaping dough. It utilizes conical components, guide rails, and spiral tracks that mimic manual hand-rolling techniques, providing perfect contact angles and smooth, automatic rolling action. The guide rail design is carefully calibrated to maintain the correct contact between the guide rail and the conical body, which guarantees uniform roundness in every dough piece. Additionally, the equipment’s precise assembly, including the spiral track and conical contact points, ensures each dough ball is shaped consistently, regardless of slight variations in dough moisture or texture.

The machine’s cutting servo system offers sensitive response and accurate control of dough portioning, maintaining consistent weight for each piece. Its adjustable settings allow operators to modify the size and weight of the dough balls, accommodating different recipes and production needs. The use of food-grade stainless steel, with nano-ceramic or Teflon coatings, minimizes sticking and facilitates easy cleaning, ensuring hygienic operation and consistent quality over long production runs. Its ability to operate continuously for up to 12 hours without failure, combined with stable performance and reliable components, guarantees that each dough ball is perfectly shaped and weighed, supporting uniform baking results, improved product appearance, and higher standards of quality.

Leave a Reply