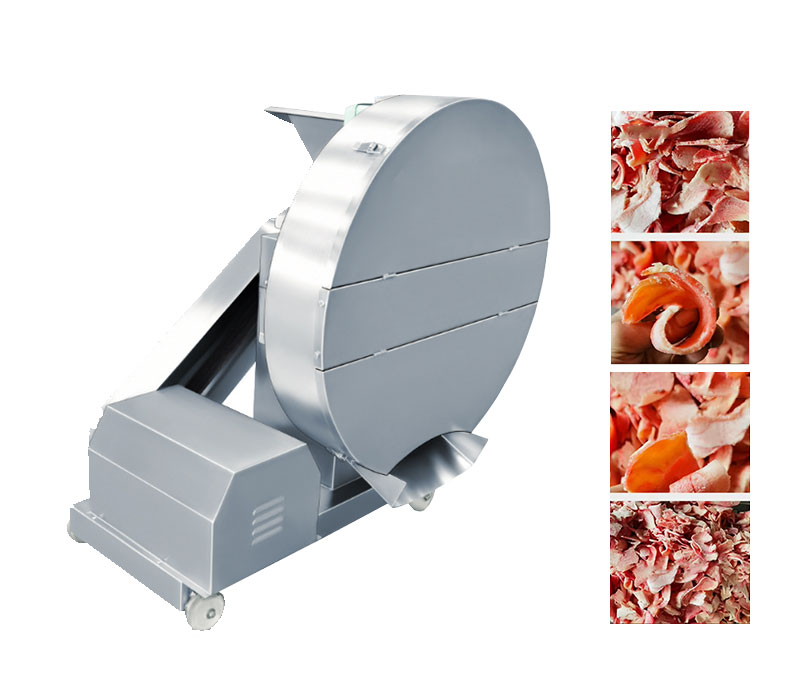

Why is a frozen meat flaker machine a smart investment for our meat processing industry?

Investing in a frozen meat flaker machine is a strategic decision that enhances efficiency, quality, and cost-effectiveness across various food service and processing businesses. It eliminates the time-consuming and costly thawing process by directly cutting frozen meat (at temperatures as low as -18℃) into slices or chunks, preserving meat freshness, nutrients, and moisture. This direct processing significantly shortens your production cycle and reduces refrigeration expenses. Its high-speed cutting capability delivers exceptional work efficiency, making it indispensable for meat processing plants, snack food factories, and restaurants. The machine’s robust construction ensures stability and reliability. Constructed from food-grade 304 stainless steel, it guarantees hygiene, is easy to clean, and offers a durable solution. By producing uniform slices, it seamlessly integrates with subsequent processes like choppers or grinders, reducing manual labor intensity, improving meat quality, and extending the lifespan of related equipment. This makes it an essential tool for maximizing output, maintaining product integrity, and streamlining operations.

What are the primary applications of frozen meat flaker machine in meat processing industry?

Frozen meat flaker machine is essential pre-processing equipment for a wide range of meat products. Their primary application is to directly slice or shred frozen boneless meat blocks (such as pork, fish, chicken breast, beef, and lamb) at temperature -18℃, completely eliminating the need for thawing. This capability is crucial for efficiently producing minced meat required for various subsequent processes.

These machines are widely utilized in:

- Sausage production: Ham sausage, hot dog, and general sausage processing plants: They prepare frozen meat into the correct consistency for grinding and stuffing.

- Meatball production: They efficiently mince frozen meat plates, providing an ideal base for mixing and forming meatballs.

- Canned meat product manufacturing: They ensure the meat is properly processed for canning.

By directly processing frozen meat, these slicers/shredders prevent the loss of moisture and protein, thus maintaining meat freshness and quality. They significantly improve work efficiency by saving time and labor, and their integration with other meat processing equipment like meat grinders, sausage stuffers, meat pasters, and meatball machines makes them an indispensable part of a streamlined production line.

What are the essential steps and precautions for safely operating a meat flaker?

To ensure safe and effective operation of your meat slicer, follow these guidelines:

1. Usage Steps:

- Stable Setup: First, ensure the equipment is securely placed on a stable, horizontal surface.

- Power Connection: Connect the power supply according to the provided instructions.

- Grounding: Verify that the machine’s casing is firmly grounded for electrical safety.

- Blade Check: Before starting, inspect the blades for looseness and tighten them if necessary.

- Starting Procedure: Initiate operation by rotating the blades in the correct direction (follow the arrow indicator). If they rotate in reverse, adjust the connection of any two power cords.

2. Important Precautions:

- Electrical Safety: Never wash electrical parts with water.

- Operator Safety: Do not place your hands into the feed inlet at any time.

- Foreign Object Prevention: Take measures to prevent foreign objects from entering the machine.

How does the meat flaker machine’s construction contribute to its reliability and long-term performance?

This machine is built as an industrial-grade workhorse for demanding environments. Its integral welded structure provides exceptional stability, minimizing vibration and noise during operation. The use of high-hardness alloy steel or tungsten steel blades ensures they remain sharp longer, resist cracking, and deliver clean, precise cuts without tearing meat fibers, thus reducing waste and blade replacement frequency. The robust construction, combined with a powerful 4kW motor and pneumatic pushing system, allows for strong load resistance and continuous operation. Furthermore, its low failure rate and easy maintenance contribute to its overall reliability and long service life.

Can this machine be integrated into an existing automated production line, and how does meat flaker benefit my overall workflow?

Absolutely. This frozen meat flaker machine is designed for seamless integration into automated production lines. It supports the use of hopper carts and custom conveyor belts, allowing for continuous, non-stop feeding and efficient material transfer. By acting as an ideal pretreatment solution, it prepares meat perfectly for subsequent equipment such as meat grinders, choppers, and sausage stuffers. This integration not only streamlines your overall production flow but also extends the service life of your downstream machinery by providing them with consistently processed, optimally sized raw materials. This elevates your pretreatment workflow and contributes to achieving superior end-product standards.

Leave a Reply