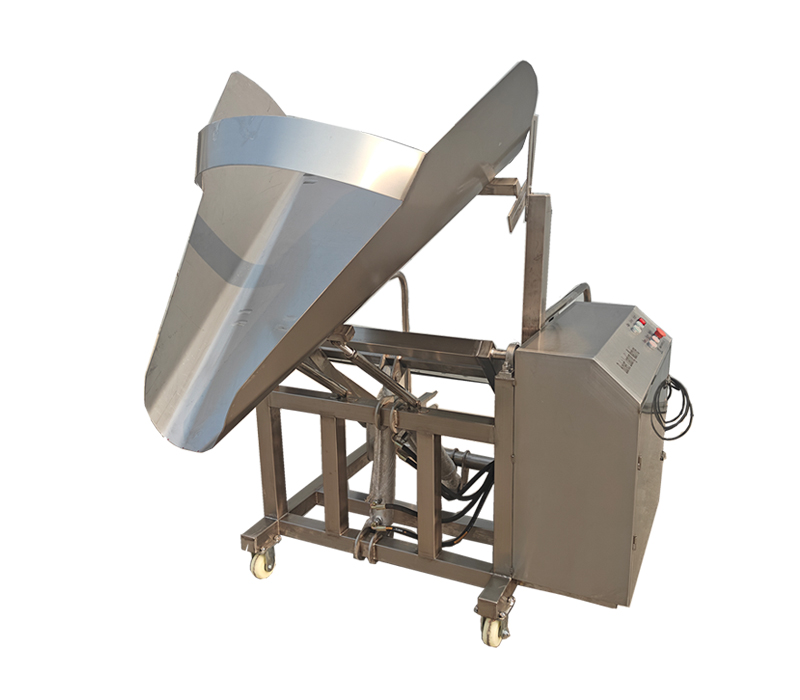

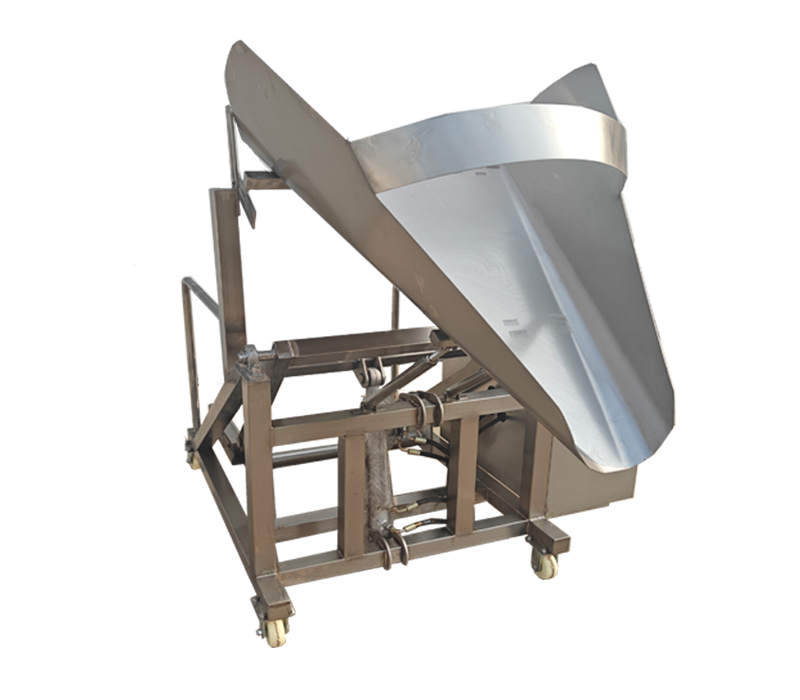

Hands-free tray aligning machine offering precise placement, hygienic stainless design, quiet operation and easy line integration.

Marker

- Home

- Products

- Cooking Mixer

- Sausage Process

- Blast Freezer

- Fish Processing

- Meat Preparation

- Meat Portioning

- Coating

- Flour Process

- Bread Braiding Machine

- Dim Sum Machine

- Bakery Proofer

- Spring Roll Wrapper Machine

- Chapati Press Machine

- Gau Bau Bun Machine

- Bakery Oven

- Momo Machine

- Steam Cabinet

- Noodle Machine

- Tortilla Machine

- Gyoza Grill

- Dough Divider

- Dough Mixer

- Dough Rolling Machine

- Dough Sheeter

- Dumpling Maker

- Dumpling Wrapper Making Machine

- Baguette Moulder

- Bread Slicer

- Toast Moulder

- Tortilla Roti Chapati Pita Arabic Bread Making Machine

- Vegetable Process

- Colloid Mill Machine

- Blanching Pasteurizer Machine

- Pumpkin Peeling Machine

- Garlic Peeling Machine

- Vegetable Cutting Machine

- Wave Potato Cutting Machine

- French Fries Cutting Machine

- Leafy Vegetable Cutting Machine

- Vegetable Stuffing Chopping Machine

- Multifunctional Vegetable Cutting Machine

- Multipurpose Vegetable Cutting Machine

- Root Vegetable Cutting Machine

- Vegetable Cube Dicing Machine

- Potato Peeling Cutting Machine

- Mini Vegetable Cutting Machine

- Dewatering Deoiling Machine

- Vegetable Washing Machine

- Washing Machine

- Air Cooling Drying Machine

- Packing Machine

- Food Dehydrator Machine

- Refrigeration and Freezer

- Applications

- Services

- blog

- contact

Leave a Reply